Concrete is the most widely used construction material in the world, but it is also one of the materials that significantly impacts the environment. Engineers in Japan have developed a technique to create “green” concrete by recycling waste concrete and combining it with captured CO2.

It is estimated that up to 8% of global CO2 emissions result from the concrete production process, with most of that coming from heating limestone to very high temperatures to produce calcium, a key component in the chemical reaction that forms concrete.

Up to 8% of global CO2 emissions are a result of concrete production.

Previous research has explored ways to reduce or replace binders, utilize captured CO2 in the mix, or even enhance the ability of the final product to absorb CO2 from the atmosphere.

In this new study, researchers from the University of Tokyo and others have developed a process that reduces the environmental impact of concrete in several ways. First, the new material is made from old concrete piles, which are often wasted and discarded because they have outlived their usefulness.

This not only extends the life of old materials but also allows the process to be carried out at around 70°C, much lower than the temperature required to heat limestone at over 1,000°C. Another benefit is that the mixed CO2 can be sourced from industrial emissions or directly captured from the environment.

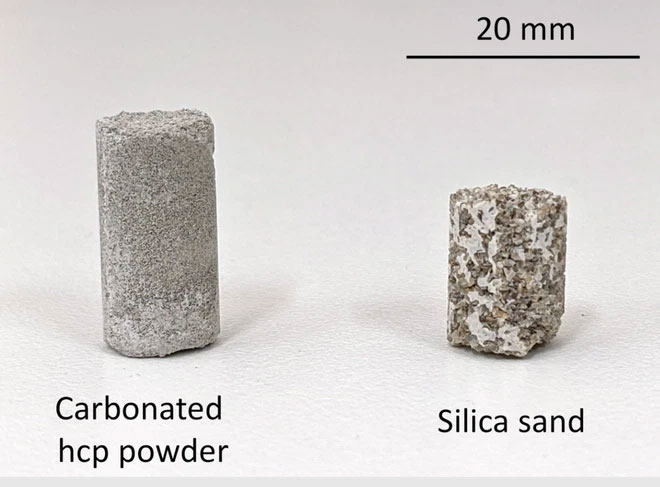

In their experiments, the research team created sample blocks from one of two common construction wastes, hardening cement paste (HCP) or silica sand. The process starts with a calcium bicarbonate solution made from limestone powder, deionized water, and CO2 gas. This solution is then pumped into a mold containing one of the aggregates, either HCP powder or silica sand, and heated to 70°C. The final result is a new material block that the research team calls calcium carbonate concrete.

The new material block that the research team calls calcium carbonate concrete.

Although it is better for the environment, calcium carbonate concrete is not yet as strong as desired. The average compressive strength of the blocks is 8.6 MPa, significantly lower than the 20 to 40 MPa of concrete made from Portland cement. However, the research team believes it could still be usable in small-scale buildings and can be further improved in the future.

Takafumi Noguchi, one of the study’s authors, stated: “It is exciting to make progress in this field, but there are still many challenges to overcome. Along with increasing the strength and size limitations of calcium carbonate concrete, it would be even better if we could reduce energy consumption during the production process. However, we hope that in the coming decades, calcium carbonate concrete will become the dominant type of concrete and will be one of the solutions to combat climate change.”

The research has been published in the latest issue of the Journal of Advanced Concrete Technology.