|

|

Orville Wright and Henry Ford |

Henry Ford was not the inventor of the automobile, nor did he discover the assembly line method of production. His idea for assembly came during a visit to a meatpacking plant in Chicago. At the meatpacking facility, animals were slaughtered and skinned, then hung on hooks along a slow-moving conveyor line. At each stop, workers cut various parts of the meat until only the animal’s skeleton remained at the final station. Henry Ford reversed this process and applied the assembly method to the automobile industry.

Starting in 1910 at the Highland Park automobile factory, Henry Ford and his team of efficiency experts surveyed new methods daily to increase productivity, a process that lasted for 17 years. Ford’s motto was “Everything can always be improved upon from the way it is currently done.” In the assembly line method, timing and coordination of actions are crucial. The conveyor belt brought parts to the workers, and each person performed specific tasks, such as tightening bolts or attaching components. This new system reduced the assembly time of a car from 12.5 hours in 1912 to just 1 hour and 15 minutes by 1914. By the end of that year, 13,000 Ford employees produced 260,720 cars, compared to the 66,350 workers at other companies who manufactured 286,770 cars.

Many criticized Henry Ford for turning workers into automatons who could not think, as the assembly line method diminished the need for mechanical skills. However, Ford argued that higher skills were utilized in the planning, management, and production phases, thus allowing unskilled workers to effectively use these skills.

In the early 20th century, most workers were unskilled immigrants, typically working nine-hour days for a wage of $2.38 per day.  Due to the low skill levels of workers, the rejection rate after the probation period was notably high. In 1913, Ford’s company had to select 963 candidates to acquire just 100 workers for the payroll. To maintain a workforce of 13,000, Henry Ford continuously invested in short-term technical training. Additionally, Ford’s company started offering bonuses, health insurance, and provided recreational facilities for workers and their families.

Due to the low skill levels of workers, the rejection rate after the probation period was notably high. In 1913, Ford’s company had to select 963 candidates to acquire just 100 workers for the payroll. To maintain a workforce of 13,000, Henry Ford continuously invested in short-term technical training. Additionally, Ford’s company started offering bonuses, health insurance, and provided recreational facilities for workers and their families.

On January 5, 1914, Henry Ford announced a minimum wage of $5 per day for an 8-hour workday, along with a profit-sharing program. Ford was celebrated by many cities as a friend of workers and a socially progressive figure. However, other business leaders, including some shareholders of Ford Motor Company, considered him a threat to the company’s stability and viewed his solutions as irresponsible. In reality, Ford recognized the importance of human factors in mass production, believing that a happy workforce would lead to higher productivity. Between 1914 and 1916, Ford’s profits rose from $30 million to $60 million, and the new wages for Ford workers turned them into customers for the company’s cars.

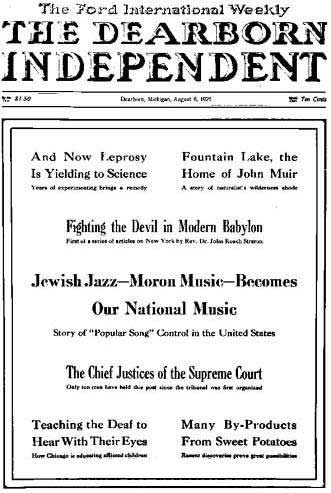

The success of the Ford Model T had a profound impact on social, economic, and cultural spheres, and Henry Ford was regarded as a hero. Despite this, Henry Ford was not satisfied. Just before the United States entered World War I, he, along with 170 others, chartered the ship “Peace” to France without U.S. government approval, naively intending to prevent the war. In 1918, he ran for the U.S. Senate as a Democratic candidate in Michigan but lost, yet continued to speak out on political issues. In 1919, he purchased the newspaper The Dearborn Independent, which became notorious for its anti-Semitic articles.

—————————————

Return to: “Henry Ford: The Father of the Automobile Industry“

Read: “The Nature of Henry Ford“