This is the achievement of Adamant Namiki Precision Jewel Co. in collaboration with researchers from Saga University, Kyushu, Japan. Thanks to these studies, they have discovered a method to mass-produce artificial diamond memory chip wafers with a diameter of 5 cm. This wafer format is a promising solution for quantum storage and computing systems.

The current challenge in quantum computing storage lies in the purity of the carbon crystals in artificial diamonds. If the memory chips contain too much nitrogen, the data storage capacity will be compromised. The newly developed diamond wafer by the Japanese has a purity level of 3 parts per billion, meaning that for every billion atoms on the wafer, there can be no more than 3 nitrogen atoms.

This chip has been named Kenzan Diamond by scientists.

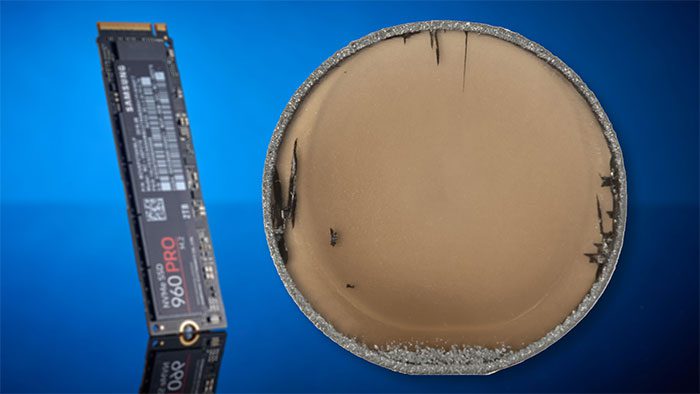

As a result, this 5 cm diameter wafer can store 25 exabytes of data, equivalent to the data capacity of 1 billion single-layer Blu-Ray discs, each with a capacity of 25 GB. Scientists have named it Kenzan Diamond. To put it into perspective, this wafer, which is only three times larger than a coin, can store an amount of data equivalent to 25 million 1TB NVMe SSDs that we use daily.

Prior to the Japanese achieving such a “gigantic” wafer, artificial diamond memory solutions that met the standards for use in quantum computers typically only measured a mere 4 square millimeters. Thus, despite its diameter of just 5 cm, this wafer size is indeed enormous. Thanks to these new solutions, it is possible that in the very near future, the advantages of quantum computers over traditional computing will become a reality, such as the application of qubits with values between 0 and 1 for extremely fast computations.

Diamond memory wafers are now produced by “growing” carbon crystals in a containment vessel, resulting in flat and thin artificial diamonds. In general, for artificial diamonds, to increase the success rate of growth, nitrogen is added as a catalyst. However, due to this catalyst, the purity of the diamond memory chip is insufficient for the conventional artificial diamonds used in quantum computing.

The fundamental issue in the production of diamond memory chips is that under high pressure, the flat and thin artificial diamond wafers can crack, thereby reducing their operational capacity when used with quantum computers. For the new solution, the Japanese research team utilizes a containment vessel designed like stair steps to minimize pressure during growth, resulting in the creation of much larger wafers.

Adamant Namiki plans to commercially produce the Kenzan Diamond in 2023, while simultaneously seeking to manufacture diamond memory chip wafers with a diameter that is double the current size.