New Technology Enables 3D Printing of Satellite Antennas in Orbit Using Plastic and Solar Light, Significantly Reducing Launch Costs.

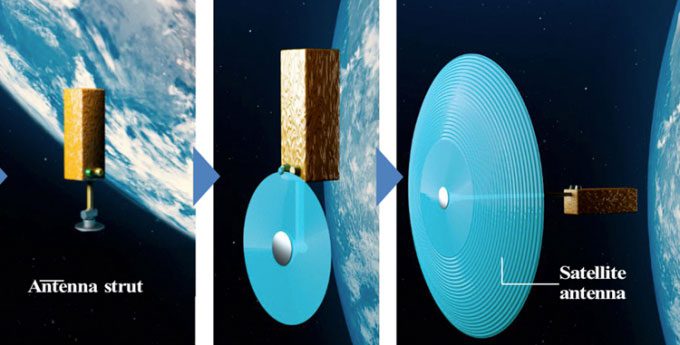

Satellite antennas can now be 3D printed in space using sunlight, thanks to a new method that promises to eliminate bulky satellite components that take up valuable space in rockets, as reported by Space on May 21. This innovative method, developed by the Japanese technology company Mitsubishi Electric Corporation, has been patented. Experts utilize a special resin that hardens into a sturdy material when exposed to ultraviolet radiation from the sun in space.

Simulation of a satellite launched into space, then using new technology to 3D print an antenna dish. (Photo: Mitsubishi Electric Corporation)

So far, Mitsubishi Electric Corporation has only tested the technology under simulated space conditions in a testing chamber. During these tests, the research team successfully printed a 16.5 cm wide antenna dish that operates similarly to traditional satellite antennas.

The sensitivity of the antenna is directly related to its size. Larger antennas are better at detecting and transmitting signals. However, size poses a significant challenge when launching into orbit, as larger antennas take up considerable space in the rocket. Additionally, antennas must be sturdy enough to withstand vibration during launch, making them heavier. Heavier satellites lead to higher launch costs.

3D-printed components in space will be much lighter because they do not have to endure the vibrations of a launch. Therefore, by directly 3D printing antennas in space, operators can save money with lighter satellites. Moreover, they can equip smaller satellites with much larger antennas than currently possible.

Designing antennas for spacecraft presents numerous challenges due to conflicting requirements for signal transmission, bandwidth, and lightweight construction. The new technology paves the way for 3D printing massive structures in space, which would otherwise not fit in rockets, according to Mitsubishi Electric Corporation.

The light-sensitive resin also exhibits excellent heat resistance, functioning at temperatures up to 400 degrees Celsius, exceeding the conditions spacecraft must endure in low Earth orbit. Mitsubishi Electric Corporation states that this is the first resin suitable for use in a vacuum environment, as it does not require atmospheric oxygen to prevent it from solidifying too quickly. Utilizing natural ultraviolet light also helps reduce the power consumption of the 3D printer.