A small shop in Minokamo City, central Japan, has received countless orders from all over the country, thanks to the Kaketsugi technique, or repairing clothing to look as good as new.

The shop, named Oriwa Giken, is run by a father-daughter team. The father, Tesshu Kataoka, 78 years old, has over 40 years of experience, while his daughter, Yoshiko Goto, 44 years old, learned the craft from him. With their incredible sewing skills, they can transform damaged or torn fabric back to a state that looks completely new. Japanese media refer to this as the “invisible patching technique”, according to The Mainichi.

The “invisible patching” technique of the master craftsmen Tesshu requires great precision and patience.

Performance in New York

Mrs. Yoshiko never thought she would have the opportunity to demonstrate her traditional technique in front of a crowd in New York City (USA) in May 2019. About 200 attendees applauded continuously after she repaired a 2cm hole in a wool fabric. “My hands trembled with anxiety”, she recalled the moment at the event organized by the Japan Association in New York City.

The invitation from New York began with a request to repair a satin kimono that had been damaged. Thanks to the excellent skills of the father and daughter duo, a several-centimeter tear completely disappeared from the fabric, even though the kimono was made from a thick and complex weave. The special client was the online kimono laundry service Yokohama Choujiya, which sought a craftsman capable of restoring the kimono for the Japan Association’s performance in New York.

The technique of Oriwa Giken is considered the best among the artisans that Yokohama Choujiya had contacted. Before the performance, the Japan Association released a short film showcasing Mrs. Yoshiko’s craftsmanship, titled “Invisible Patch: The Miracle of Kimono Restoration.” The film immediately attracted a lot of attention and quickly spread online. Viewers were amazed by the incredible technique, as the Japanese woman could “magically” mend tears and holes, restoring the garment’s surface to its original state.

Kaketsugi Technique

The “invisible patching” technique originates from the skilled hands and tireless efforts of father Tesshu. Based on a technique he invented, he can repair holes caused by moths, burns from cigarette butts, or tears in clothing. In his youth, Tesshu took over the family tailoring shop. Over time, ready-made clothing became increasingly popular. Faced with the risk of closing down, he decided to explore the Kaketsugi technique on his own. He started from scratch, analyzing fabric fibers and the weaving methods of different materials.

After countless days and nights of hard work honing his skills, he mastered the drawing of each fabric structure and completed records of various fabric samples. Over the years, Tesshu self-improved his tools and the “patching” technique, or more accurately, meticulously rewove by hand the torn fabric on each garment. For example, he devised special needle patterns to perform Kaketsugi and also collected fabric from parts like pockets and linings of garments. He then passed this craft on to his daughter.

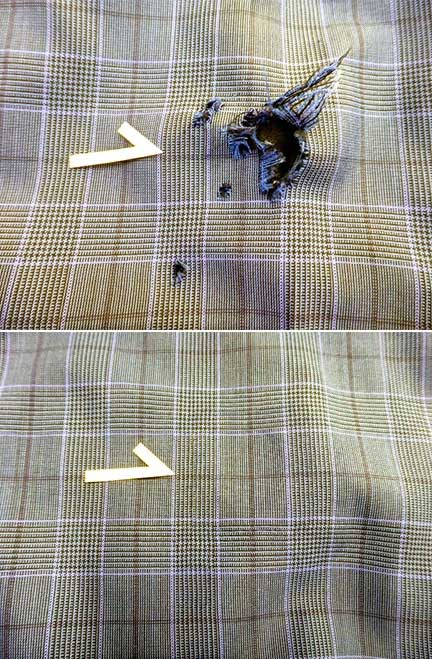

It is essential to have enough fabric of the same pattern to patch a hole. If not available, the craftsman can use the inner fabric of the garment. The sewing process requires precise and careful craftsmanship. In a video posted on NHK’s website, the shop received an order for a vest with a hole caused by a cigarette burn. Mrs. Yoshiko analyzed the weaving method of the vest fabric and concluded that it had four fibers per millimeter. She observed how the fibers overlapped and carefully rewove them. It took about 40 minutes to complete just 1cm. A week later, the repaired vest was sent back to the customer. If not marked beforehand, the customer would not even notice where the hole had been.

In 2016, Oriwa Giken launched a website and began accepting orders from all over Japan. Their target audience consists of customers who are reluctant to throw away clothing with sentimental value. Each year, they receive and complete about 2,000 garments. Both the father and daughter find joy in seeing their customers delighted with the restored outfits. “I take pride in the fact that damaged clothing can continue to be used for a long time, especially in this era of material abundance,” Mrs. Yoshiko shared.

The tears and holes have completely disappeared thanks to Mrs. Yoshiko’s artistry.

Mrs. Yoshiko stated that her experience in the U.S. inspired her to set a new goal: “I want to accept orders from abroad and make Kaketsugi a technique recognized worldwide.” She and her father Tesshu hope to explore and analyze the structures of various fabrics from around the world. “There are still many fabric structures I am not familiar with. I am very much looking forward to taking on new challenges,” said the artisan.