Hyundai Engineering’s New Facility Set to Utilize Organic and Plastic Waste to Produce 30,000 Tons of Hydrogen Annually.

Hyundai Engineering has unveiled plans for facilities that will convert organic waste into hydrogen and plastic waste into hydrogen at the H2 Mobility Energy Environment Technology (MEET) workshop held in Seoul from September 25 to 27. These two plants are expected to produce over 30,000 tons of hydrogen each year, making them the largest facilities of their kind in the world.

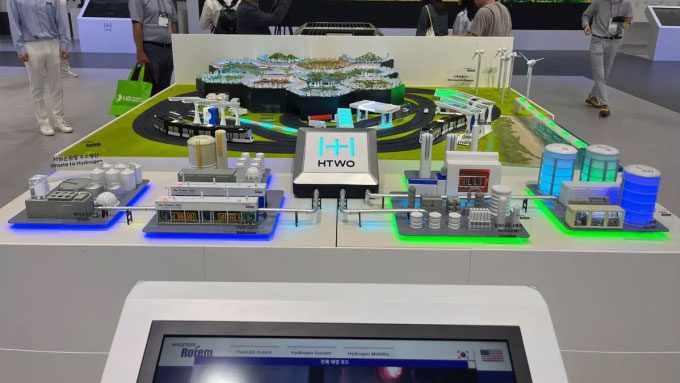

Hyundai Engineering’s Waste-to-Hydrogen Facility. (Photo: Kapil Kajal/Interesting Engineering)

Organic waste such as food scraps, sewage sludge, and livestock manure generates large amounts of methane, contributing to global warming. The waste-to-hydrogen conversion technology not only helps manage this methane, preventing further global warming, but also creates new industrial value by producing hydrogen—a cleaner energy source.

Initially, organic waste will undergo anaerobic decomposition by microorganisms. This process transforms the waste into biogas. Next, the biogas is upgraded to biogas methane, removing CO2 and impurities. Finally, the biogas methane is converted into hydrogen.

In addition to organic waste, Hyundai’s new facility will also convert plastic waste into hydrogen. The first stage is a “pre-treatment” phase, eliminating impurities such as metals, sand, and paper to create a clean plastic waste material. Following this, a “melting” process developed by Hyundai Engineering heats and stirs the plastic waste to melt it into a viscous state. This process continues to remove smaller impurities.

During the gasification process, the melted plastic is liquefied and fed into a gasification unit with oxygen and steam to produce syngas comprising CO and hydrogen using Shell’s technology. Finally, in the syngas refinement stage, additional hydrogen is produced through the conversion of CO, impurities in the syngas are removed, and CO2 is separated. As a result, the plant successfully generates high-purity hydrogen from plastic waste.

With 130,000 tons of plastic waste, the facility can produce approximately 24,000 tons of hydrogen per year using environmentally friendly methods. This hydrogen can be used in various applications, including as fuel for the maritime industry and electric vehicles.