Researchers at Johns Hopkins University have developed a new shock-resistant material that is as hard as metal but as light as foam.

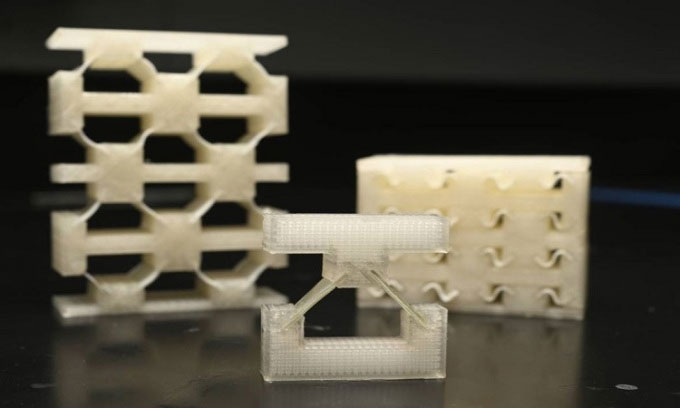

LCE particle material in various shapes. (Photo: Johns Hopkins University)

The new material is primarily made from liquid crystal elastomer (LCE) particles, which can be used to manufacture helmets, body armor, and lightweight, durable vehicle parts that are reusable. LCE is a polymer network in the liquid crystal phase, combining elasticity and stability. LCE is typically used to create actuators and artificial muscles for robots. However, in a recent study published in the journal Advanced Materials, scientists explored the energy absorption capabilities of the material.

The research team created materials consisting of multiple inclined LCE beams sandwiched between rigid supporting structures. This basic unit repeats in multiple layers to bend at various levels upon impact, effectively dispersing energy. In a series of experiments, scientists tested how well the new material could withstand impacts from different weights at varying speeds. They subjected objects weighing 1.8 to 4.5 kg to collide with the material at speeds of up to 35.4 km/h.

The material performs better with more layers. For example, a 4-layer structure has nearly double the energy absorption density compared to a single-layer structure. Although the material has only been tested at impact forces of 35.4 km/h so far, the research team indicated that the product could withstand impacts at higher speeds. This material could enhance the safety of helmets, bulletproof vests, and automotive bumpers.

“We are very excited about the exceptional energy absorption capabilities of the new material,” said researcher Sung Hoon Kang, assistant professor of mechanical engineering. “The material provides better protection against impacts while being light enough to reduce fuel consumption, environmental impact, and enhance comfort for the wearer of protective gear.”