SeaBrick, a company based in Canada, is developing floating bricks made from seaweed that could serve as a foundation for structures on the ocean.

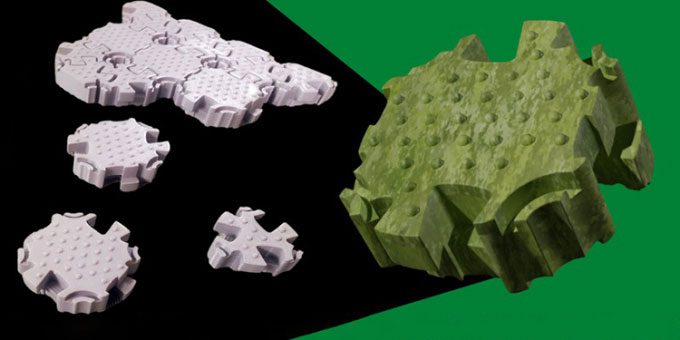

SeaBrick floating bricks made from seaweed. (Photo: Seasteading)

With rising sea levels, many cities and even entire countries face the risk of being submerged. SeaBrick is aiming to build infrastructure on the water’s surface using environmentally friendly floating bricks, as reported by Interesting Engineering on February 22.

SeaBrick bricks are described as an interlocking system that can create a platform, similar to Lego pieces. The company utilizes kelp from the ocean to make them buoyant. Other essential components include red clay, which covers 38% of the ocean floor, and sargassum, a large brown algae that often grows excessively in coastal waters, causing problems for local ecosystems.

While governments and non-profit organizations spend significant time and money to remove sargassum, the use of SeaBrick bricks not only helps to clean these waters but also provides income for communities affected by them.

SeaBrick could provide a revolutionary building solution on the ocean. (Photo: Seasteading).

Producing kelp and sargassum also helps sequester carbon from the atmosphere, with an efficiency over 20 times greater than terrestrial forests. Compared to floating concrete structures, using SeaBrick for construction is estimated to save 72% in costs while generating lower carbon emissions, according to Seasteading, a research institute established to support building mobile communities on floating platforms in international waters.

SeaBrick has partnered with Seasteading with a shared vision of “decarbonizing the global construction sector while supporting vulnerable coastal communities.” The founder of SeaBrick believes that using floating bricks made from kelp and sargassum could help the planet sequester millions of tons of CO2 permanently.

Additionally, this technology could support green energy projects such as wind farms, tidal energy, and offshore solar power, helping us transition from our current extractive economy to a regenerative economy, where used kelp can be easily renewed.