The most robust part of the plant is not the roots or the trunk, but the walls of the microscopic cells.

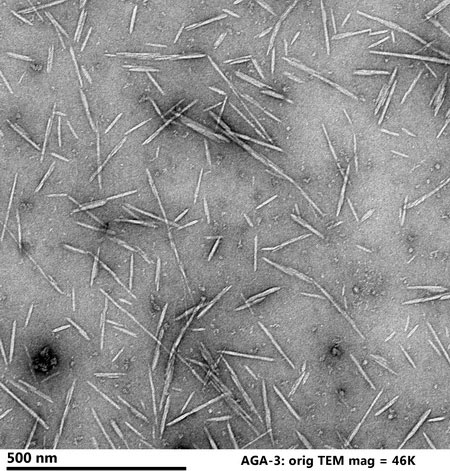

A single wood cell is made up of cellulose fibers – a natural, flexible polymer that forms the structural component of all plants. Within each fiber of this material are reinforcing cellulose nanocrystals (CNC); these are organic polymer chains arranged in nearly perfect crystalline formations.

At the nano scale, CNC is stronger than Kevlar armor and has the potential to produce more durable, environmentally friendly natural plastics.

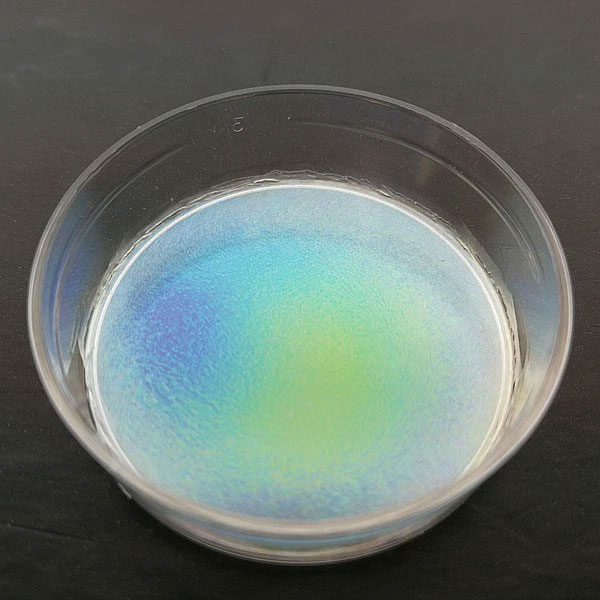

A layer of cellulose nanocrystals in a petri dish.

To achieve this goal, a team of researchers at MIT has created a synthetic material made from cellulose crystals combined with a small amount of synthetic polymer. The organic crystals make up 60-90% of the material composition; the scientists also set a record by creating the largest amount of CNC-containing material ever.

This new material is tougher than some forms of rigid bone and is also harder than aluminum alloys still used in manufacturing. The microstructure of the new material can be compared to the glossy nacre layer commonly found in mollusk shells.

The glossy nacre layer in a shell.

The formula for creating the new CNC-containing compound allows scientists to both 3D print the material and cast it in the traditional way. “By creating a compound with a large amount of CNC, we can impart unprecedented properties to polymer-based materials,” said A. John Hart, a professor involved in the project.

“If we can replace petroleum-based plastics with natural cellulose, this could improve the [condition of] our planet.”

A Flexible Composite

Each year, industrial production lines synthesize over 10 tons of cellulose from the bark, wood, and leaves of plants. Most of it is used in paper or textile production, with a small portion used in food processing or cosmetics.

Lignin wood containing cellulose nanocrystals.

In recent years, science has begun to take notice of the nano-crystalline structure of cellulose, which can be easily extracted through acid hydrolysis. However, efforts to incorporate CNC into materials have faced many challenges, as these crystals tend to clump together and do not adhere well to polymer molecules.

Professor Hart and his colleagues have been tirelessly seeking ways to create a composite material with a high CNC content that can be easily molded into beneficial shapes. They plan to mix CNC and polymer into a viscous gel suitable for 3D printing or casting. By using ultrasonic technology to break up clumps, the team has been able to enhance the bonding of the composite materials.

“Basically, we break down wood and then reassemble it,” researcher Abhinav Rao explained. “We take the best part of the wood, which is the cellulose nanocrystals, and restructure them into a new composite material.”

Robust Materials

When examining the structure of the compound under a microscope, the team discovered that the cellulose particles were arranged in a structure similar to the nacre layer found in many mollusk shells. This type of structure is inherently resistant to cracking, making the new material even more durable.

A 3D printed object from the new material, with strength comparable to aluminum used in industry.

During testing, the team found that the cellulose particles helped the material resist breaking apart even when cracked. This resilience makes the material a promising composite, embodying the toughness and flexibility of both metals and plastics.

In the near future, the research team continues to seek ways to minimize the material’s volume reduction during hardening. At a large scale, volume reduction can cause structural instability in the object.

“If we can prevent the material from shrinking, we can continue to scale up the project, with objects that could reach several meters,” researcher Rao noted. “If we dream big enough, we could even replace a significant portion of plastics with cellulose-derived composites.”