Japanese scientists have developed an alloy that is as hard as steel yet as elastic as rubber when environmental conditions change, while being over 20 times more flexible than conventional alloys.

A highly flexible alloy, created from titanium and nickel by researchers at the National Institute for Materials Science (NIMS) in Japan, could play a crucial role in the construction of shape-shifting aircraft or super-strong artificial muscles.

Shape-shifting aircraft remain a concept in science fiction, as scientists struggle to develop a material that is flexible enough to achieve the shape-shifting effect while also strong enough to withstand the rigors of flight. However, this alloy, which has the strength of steel but can stretch like rubber when environmental conditions change, brings hope for the development of specialized flying devices.

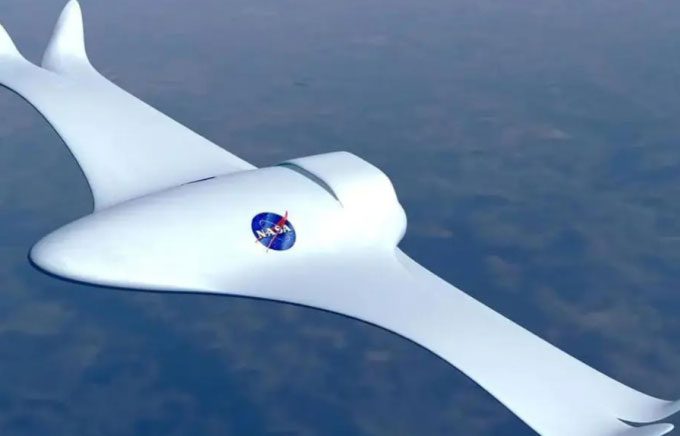

NASA simulation of a future aircraft. (Photo: NASA).

Previous research has identified that the titanium-nickel alloy possesses unique properties, such as the ability to stretch to much higher limits than other metal alloys while retaining its new shape. As the temperature of the alloy increases, it can also revert to its original shape.

While this makes the alloy an excellent candidate for manufacturing shape-shifting aircraft, researchers have faced challenges in utilizing it due to temperature limits under which the alloy retains these properties.

Although the material is very strong and flexible, it only exhibits these properties at specific temperatures, significantly limiting its applications. A research team led by Professor Xiaobing Ren at NIMS devised a three-step process to enable the alloy to display these properties over a wide temperature range.

First, they deformed and stretched the alloy by more than 50%, then heated it to 300 degrees Celsius before stretching it again.

In the final step, the researchers only stretched the alloy an additional 12%, but ultimately, the material can withstand pressure approximately 18,000 times that of normal atmospheric pressure, making its strength performance comparable to steel while also being over 20 times more flexible than conventional alloys.

More importantly, the titanium-nickel alloy also exhibits this property over a wide temperature range from -80 degrees Celsius to 80 degrees Celsius.

In an interview with New Scientist, Professor Ren explained that the alloy displays these properties because it behaves more like glass than metal. Compared to conventional glass, the alloy has regions of “grains” that deform.

Simply put, the alloy has regions where the molecules are arranged in a way that supports the deformation of the material instead of breaking. The absence of these deforming grains in glass makes it brittle, while their presence makes this material extremely flexible.

According to the research team, the method for developing the material is quite simple, easily reproducible in other laboratories, and applicable for large-scale industrial use.