New Cement Mixture Demonstrates 17 Times Greater Crack Resistance and 19 Times Better Elasticity Compared to Standard Cement.

Inspired by the materials found in oyster shells and abalone, a team of engineers at Princeton University has developed a new cement mixture with superior crack resistance and elasticity.

Drawing inspiration from nature, researchers at Princeton University have created a material that outperforms cement in crack resistance and ductility – (Photo: Sameer A. Khan/Fotobuddy).

This discovery could enhance the crack resistance of various brittle materials, ranging from ceramics to concrete, according to techxplore.com on June 11.

“If we can create concrete that prevents cracks from spreading, we can make concrete harder, safer, and more durable,” stated Shashank Gupta, a graduate student in the Department of Civil and Environmental Engineering at Princeton University.

The Reza Moini laboratory at Princeton University often draws inspiration from biology to research building materials. This time, the team looked to a natural material known as nacre, found in certain types of shells like oysters and abalone.

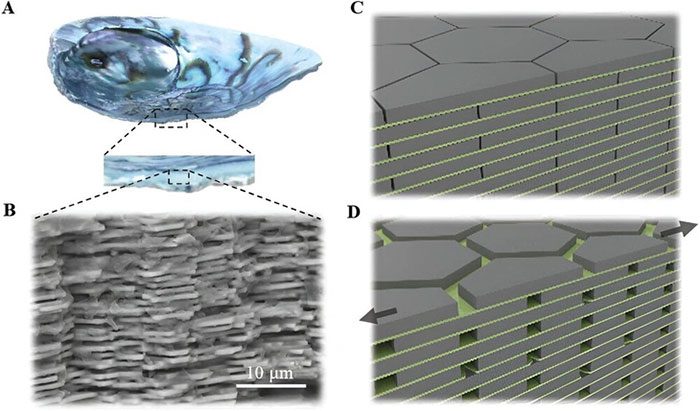

At the microscopic level, nacre consists of small hexagonal plates containing aragonite mineral crystals that are bonded together by a soft biopolymer (a type of polymer derived from biological sources). The aragonite particles significantly contribute to the strength of nacre, while the biopolymer enhances flexibility and crack resistance.

The engineering team developed improved composite materials inspired by nacre. They utilized common building materials such as Portland cement mixed with a specific amount of polymer.

The new cement mixture has a structure similar to natural and synthetic nacre. Image (A) shows a cross-section of natural nacre. Image (B) is a microscopic view of the 3D arrangement of tiles and mortar of aragonite crystals bonded by soft biopolymer. Images (C and D) depict the undistorted and distorted structural diagrams of the cement mixture – (Photo: techxplore).

The team alternated layers of cement with a highly elastic polymer known as polyvinyl siloxane (PVS) to create small cement columns. They conducted three-point bending tests to evaluate the crack resistance of the product and compared these cement columns with solid cast cement.

They found that the new cement mixture has 17 times greater crack resistance and 19 times better elasticity compared to standard cement.

The research was published in the journal Advanced Functional Materials.