To this day, the Iron Pillar of Delhi remains a “living proof” of the extraordinary skills of ancient Indian metallurgists.

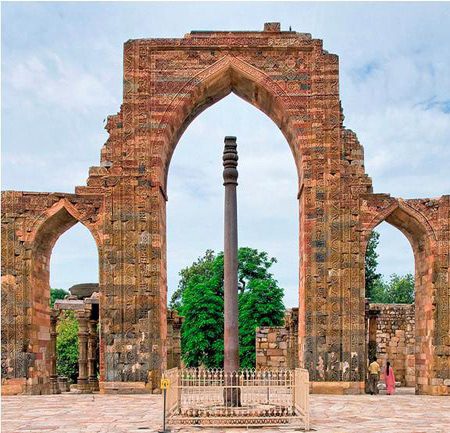

The Iron Pillar of Delhi is one of the famous ancient monuments of India. This iron pillar, erected in the 5th century by King Kumara Gupta I of the Gupta dynasty, ruled over northern India from 320 to 540 AD.

Originally, this pillar was part of the Muttra temple, adorned with a statue of Garuda at its top. However, after this Hindu temple was destroyed by Qutb-ud-din Aybak to build the Qutub Minar and the Quwwat-ul-Islam mosque, it became the only remaining part.

Interestingly, despite being exposed to the elements for thousands of years, the Iron Pillar of Delhi shows almost no signs of rust. For decades, scientists and metallurgical engineers from around the world have proposed various hypotheses about the properties of this unusual marvel.

Decoding the Mystery of the 1,600-Year-Old Rust-Free Iron Pillar

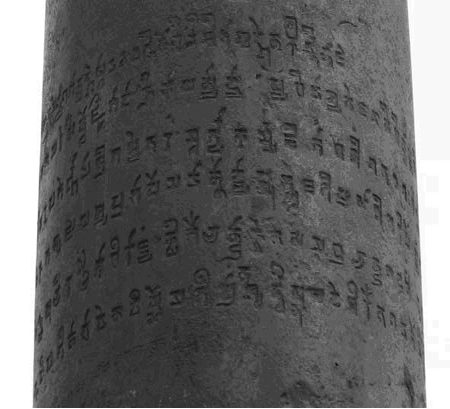

The pillar stands at a height of 7.2 meters from the ground and weighs approximately 10 tons. It was moved to its current location several centuries ago. It has endured over 1,600 years of rain and shine without any rust. Inscriptions on its surface indicate that it was erected to honor a Hindu deity and a king named Chandra—a mysterious figure that remains an enigma to historians today.

Legend has it that this iron pillar was cast in memory of King Chamdaro.

What is astonishing is that this iron pillar has stood outdoors for over 1,600 years, enduring countless storms and still showing no signs of rust.

The Iron Pillar of Delhi.

Meanwhile, iron is a metal that rusts easily after just a few decades, let alone after over a thousand years.

To this day, humanity has not found an effective method to prevent rusting of iron objects. Although theoretically, pure iron does not rust, it is difficult to smelt and extremely expensive. Furthermore, some scientists analyzed the composition of the iron pillar and discovered that it contains many impurities rather than being pure iron. According to theory, this type of iron is more prone to rusting than ordinary iron.

If we assume that the ancient Indians had already mastered the technology for rust-resistant iron, which has since been lost, why didn’t they produce other rust-resistant iron items? Moreover, in the ancient Indian iron manufacturing treatises, there is no record addressing this issue.

This iron pillar stands alone, seemingly challenging humanity’s quest for knowledge, and also symbolizes the ancient Indian civilization.

Outdated Technology Creates an Extraordinary Miracle

Ultimately, experts from the Indian Institute of Technology (IIT) have decoded the mystery behind the longevity of the Iron Pillar of Delhi. Through microscopic observation, they discovered a very thin “coat” covering the entire surface of the pillar.

Sample analysis determined that this layer is a compound of iron, oxygen, and hydrogen. This compound prevents the iron metal of the pillar from coming into contact with air. As a result, corrosion reactions due to chemical reactions cannot occur, making the iron pillar virtually immortal.

Radioisotope analysis also indicates that this protective layer began to form about three years after the iron pillar was manufactured, meaning its lifespan is equivalent to that of the pillar itself. Over more than a millennium, it has continuously thickened at a very slow rate. After 1,600 years, this layer has only reached a thickness of about 1/20 millimeter.

Ancient inscriptions remain as sharp as if freshly carved, despite thousands of years passing.

So, how did this iron pillar acquire such a valuable protective layer? A research group’s announcement surprised scientists around the world: It was the outdated metallurgy technology of the 4th century that inadvertently created this compound. Dr. Balasubramanian, the lead researcher, stated that his team found an unusually high level of phosphorus in the iron samples collected from the pillar.

The analyzed phosphorus content was over 1%, much higher than the phosphorus levels in modern iron, which is typically below 0.05%. This high phosphorus content acted as a catalyst, facilitating the reactions that led to the aforementioned protective substance.

This was an accidental achievement stemming from the still primitive metallurgy techniques of the time. The ancient Indians mixed coal with iron ore to shorten the smelting time. With this method, the phosphorus in the iron ore could not be completely removed and remained in the finished iron.

Meanwhile, modern iron smelting technology using blast furnaces can reduce phosphorus content to very low levels. The purity achieved through modern technology has made today’s iron unable to achieve the longevity seen in the Iron Pillar of Delhi.

The findings of these scientists were further supported when several weapons such as swords, arrows, and knives from India were found dating back to the same era as the Iron Pillar, and they too showed almost no signs of rust. This confirms that the primitive metallurgy techniques of that time produced this remarkable masterpiece that has stood the test of time. The long-standing mystery has finally been unveiled by scientists.