This tire is not only designed for Mars missions; it is likely to be used here on Earth as well.

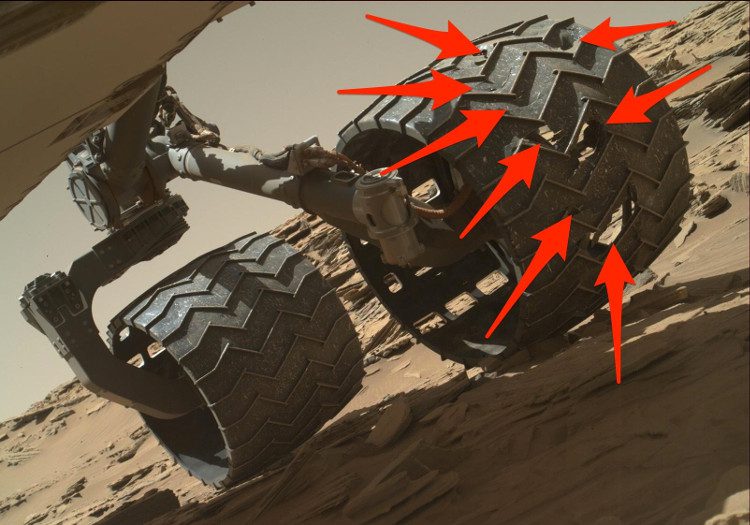

The environment on Mars is harsh and corrosive, quickly wearing out the tires of the Curiosity rover — a one-ton robot powered by nuclear energy, tasked with exploring the alien red terrain — at a dizzying rate. After just one year of travel at a speed of only 0.14 km/h (0.04 m/s), the Martian rocks had already punctured several large holes in Curiosity’s tires.

Puncturing a tire on Mars or the Moon is incredibly difficult, if not nearly impossible. Therefore, when NASA sends rovers or any wheeled exploration vehicles into space, they must ensure that those wheels cannot be punctured under any circumstances. This is when the Superelastic Tire was developed.

The Superelastic Tire has been created by NASA for future Moon and Mars missions — but as the space agency pointed out, it could also serve as a viable alternative to traditional pneumatic tires here on Earth.

NASA states: “The use of new shape-memory alloys will enable the wheels to withstand high deformation, unlike conventional elastic materials, which will allow for a tire that can endure excessive deformation without permanent damage.”

Almost eternal tires made from woven metal fibers.

They have created a nearly eternal tire made from woven metal fibers, capable of “remembering” its optimal shape and returning to that shape after being distorted or deformed by external factors.

The research and design of this special tire were conducted at NASA’s Glenn Research Center in Cleveland, Ohio. Engineer Colin Creager and his team woven metal — steel spring fibers to create the tire. It has excellent grip on soft soil and sand, able to bear heavy loads. However, there is another issue.

“We only encountered one issue; these tires always become indented after some time of use,” said engineer Creager.

Indented metal will struggle to return to its original shape.

Then he met Santo Padula, a materials scientist. Creager received advice that he should use shape-memory alloys — a type of superelastic metal that can revert to its original shape after being deformed.

“From that point, we began collaborating… to create a new type of tire, one that we believe will revolutionize the tires of planetary exploration vehicles and even innovate tires here on Earth,” Creager enthusiastically remarked.

Driving in space is as challenging as launching a spacecraft

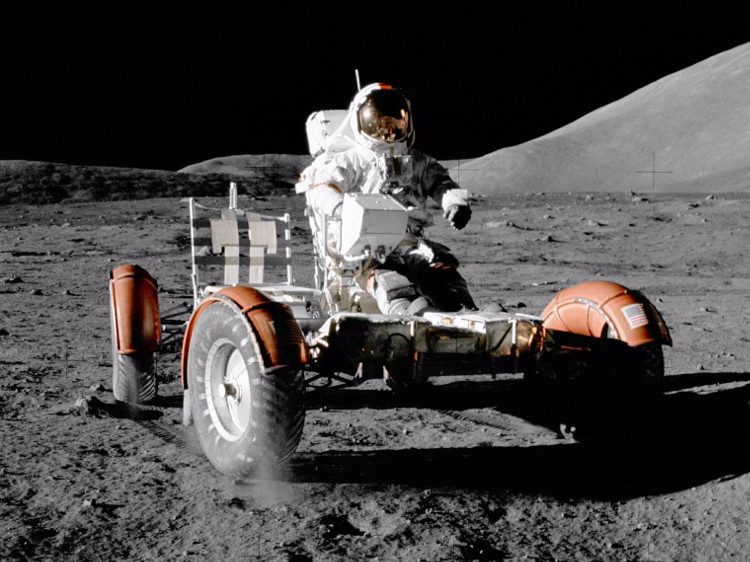

NASA has been researching and developing tires suitable for travel on other planets since the 1960s when the Moon space program began. Initially, there was the Lunar Roving Vehicle (LRV), used in Apollo missions 15, 16, and 17. The hard metal pieces helped the tires easily navigate the lunar surface, which consists of lunar dust and small gravel.

An astronaut drives on the Moon.

However, the surface of Mars is much more complex. For a vehicle to traverse it, it must meet an extensive and intricate list of requirements:

- The tires must handle all terrains: the Martian surface is made up of sand, gravel, boulders, and sharp rocks.

- The vehicle must be lightweight: it costs $30,000 to land nearly half a kilogram on the Martian surface; the lighter the vehicle, the less it costs.

- Longevity is essential: solar energy and nuclear power will help keep the vehicle operational for many years, even decades.

- It must withstand unpredictable weather: conventional rubber tires cannot survive in an airless environment where temperatures fluctuate from -129 degrees Celsius to 21 degrees Celsius in a short period.

On Curiosity, there is a tire system 50 cm high, made from aluminum and reinforced with hard metal rings both inside and out, with a V-shaped tread pattern for better traction, and a spoke suspension system to help absorb strong shocks.

Just one year after Curiosity’s Mars mission began, the tires showed concerning punctures.

However, just one year after Curiosity took on its Mars mission, the tires had developed alarming punctures. Nowadays, the vehicle must avoid areas with small gravel to minimize damage, but the tires continue to wear over time.

A new type of tire emerges

After many years of research, the team decided to utilize nickel-titanium alloy (NiTi). Springs made from steel can only be stretched 0.3% (the distance between atoms in the metal changes) before they become permanently indented and cannot return to their original shape.

However, NiTi alloy can be stretched 10% while still returning to its original shape — it has elasticity 30 times better than steel springs.

Using shape-memory alloy as a radial reinforcement component can also enhance the tire’s load-bearing capacity. The Superelastic Tire provides traction equal to or better than conventional pneumatic tires and eliminates the risk of punctures, thereby improving fuel efficiency and vehicle safety. Additionally, this tire design does not require an internal frame, simplifying and lightening the tire/wheel assembly.

NiTi alloy can be stretched 10% while still returning to its original shape.

Research results show that this new tire can carry over 10 times the weight that Curiosity’s tires can support, operate within a temperature range from -130 degrees Celsius to 90 degrees Celsius, grip rocks and sand better, and climb slopes 23% better.

In the most extreme testing scenario, over a 10 km course with challenging terrain, this tire performed excellently. Currently, NASA is building an ultra-cold testing facility to test the tires under low-temperature conditions.

A long road ahead

NASA’s tire testing.

In the coming years, NASA will launch the Mars 2020 rover — similar to Curiosity but heavier. According to Creager, unfortunately, the remarkable tire may not be applicable for Mars 2020 due to the tight timeframe and constraints. The tires still require extensive testing, and the launch deadline is approaching.

The good news for us here on Earth is that this tire can be applied right on our planet’s surface: the research team is collaborating with Goodyear — an American tire manufacturing company founded in 1898 — to implement this tire design for off-road vehicles.

Initially, it may be introduced on military vehicles operating on rugged, treacherous terrain. Creager hopes that this advanced tire technology will eventually be applicable to vehicles on paved roads as well.