Swedish researchers have developed a method to convert discarded cotton fabric into sugar, which can be used to produce spandex, nylon, or ethanol.

The lightweight industry has struggled for decades to recycle used textiles, but this type of material is notoriously difficult to recycle and often ends up in landfills.

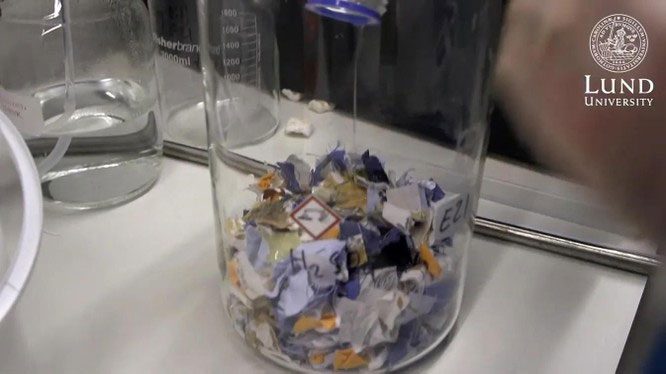

Experiment converting cotton fabric into glucose. (Image: Lund University)

To conserve this vast resource, scientists at Lund University in Sweden have invented a method to convert cotton into sugar, which can then be transformed into high-value products such as spandex, nylon, and ethanol.

Approximately 25 million tons of cotton fabric are discarded worldwide each year. When combined with other types of fabrics, the total exceeds 100 million tons of textile waste annually. In Sweden, most fabric waste is incinerated for heating residential areas. In other countries, textile waste often faces a worse fate, with old clothes frequently ending up buried in landfills.

Dr. Edvin Ruuth, a chemical engineering researcher at Lund University, notes that some fabrics have fibers durable enough to be reused, which is being done today and could be expanded in the future. However, much of the fabric becomes waste due to fibers being too short for reuse, and increasingly, all cotton fibers are becoming too short for fiber regeneration processes.

Dr. Ruuth works in the Department of Chemical Engineering at Lund, accumulating extensive knowledge about using microorganisms and enzymes, additives, and various catalysts to convert “sustainable” carbohydrates in biomass into simpler molecules. Everything from biomass waste and black liquor to straw and wood chips can potentially be turned into bioethanol, biogas, and chemicals.

In a research project led by Dr. Ruuth, the team successfully broke down the plant fibers in cotton, specifically cellulose, into smaller components without the involvement of any microorganisms or enzymes. This transformation process involves soaking the waste fabric in sulfuric acid to obtain a clear, dark amber sugar solution.

Lund University scientists testing the process of converting cotton fabric into sugar solution for producing new fabric or ethanol. (Video: Lund University).

Dr. Ruuth, who adjusted the “formula” for breaking down cotton fibers alongside PhD candidate Miguel Sanchis-Sebastiá and Professor Ola Wallberg, explains: “The key condition is to find the right combination of temperature and sulfuric acid concentration.”

The research team’s plan is to produce chemicals that can serve as raw materials for various types of textile products, such as spandex and nylon, or for ethanol production.

According to Ruuth, glucose is a highly versatile molecule with numerous potential uses, including ethanol production. From a standard piece of fabric, the research team extracted 5 liters of sugar solution, with each liter containing the equivalent of 33 glucose tablets. However, the liquid cannot be turned into sweet water due to the presence of toxic sulfuric acid.

One of the challenges is overcoming the complex structure of cotton cellulose. The uniqueness of cotton lies in its high crystallinity of cellulose. This characteristic complicates the chemical breakdown and reuse of the resulting components. Additionally, there are many surface treatments, such as dyes and other contaminants, that must be removed. Furthermore, structurally, a cotton towel and an old pair of jeans are very different.

The technology involves a highly sophisticated process to determine the appropriate acid concentration, the number of processing stages, and the suitable temperature. The idea of hydrogenating pure cotton was discovered in the 1800s. The main challenge is to make this process efficient, economically viable, and environmentally friendly.

The research team began experimenting with glucose extraction from fabric a year ago, achieving initial yields of only 3-4%. Currently, the team has reached up to 90%. Once the breakdown formula is perfected, the technique will be simple and inexpensive to apply.

This new invention from the Lund University research team opens a new direction, viewing textile waste as a raw material source for recycling into valuable chemical components for producing raw materials for synthetic fabrics or ethanol, partially reclaiming the economic value lost when textile products are disposed of in landfills.