In 1997, after attending a workshop on the application of nuclear technology in oil and gas in Beijing (China) organized by the IAEA, Nguyễn Hữu Quang recognized the significance of nuclear technology applications and the immense benefits they could bring to production. He nurtured the idea of establishing a laboratory to apply these technologies in Vietnam.

In 1997, after attending a workshop on the application of nuclear technology in oil and gas in Beijing (China) organized by the IAEA, Nguyễn Hữu Quang recognized the significance of nuclear technology applications and the immense benefits they could bring to production. He nurtured the idea of establishing a laboratory to apply these technologies in Vietnam.

Since the early 1990s, the application of nuclear engineering in industrial production was still a relatively unfamiliar concept compared to the research and application capabilities of research institutes in Vietnam.

In 1991, engineer Nguyễn Hữu Quang (from the Da Lat Nuclear Research Institute) attended a two-week course on the application of nuclear engineering in industrial production organized by the International Atomic Energy Agency (IAEA) in Indonesia. Witnessing experiments conducted by colleagues in the region, he dreamed of a day when his institute would also have similar laboratories to conduct experiments for production and engage in academic exchanges on par with them.

He reached out to engineers at the Vietsovpetro Joint Venture to gain practical insights. Noticing the need to determine the reception intervals of formations in water injection wells in granite oil fields, he decided to select this subject for his first experiment, as the marking technology was relatively simple.

The principle involves using radioactive tracer particles—known as tracers—mixed with water to be injected so that they adhere to the rock formation within the well. Subsequently, radiation detection equipment is used in the borehole to measure the radiation emitted by the tracers, thereby determining the amount of water entering the formation.

After a process of engagement and technical introduction, Vietsovpetro agreed to conduct the experiment in the Bach Ho oil field.

Due to a lack of research funding, Nguyễn Hữu Quang invested his personal finances to study experiences in China and ordered radioactive materials from the Institute of Atomic Energy. However, upon quality inspection, it was discovered that the imported tracers were unsuitable for our field conditions, leading to the entire shipment being discarded.

After researching through literature, he and his colleagues experimented and ultimately succeeded in synthesizing a tracer from radioactive gold and activated carbon. This tracer proved to be superior to the imported one and was fully compatible with Vietnam’s field conditions.

The results of the field experiments were successful, and alongside traditional methods, a new method of radioactive marking for measuring reception in injection wells was added, serving water management in oil extraction. The results were highly valued by Vietsovpetro, which allowed its application in production.

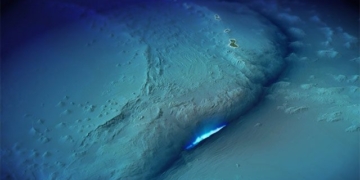

It can be said that the application of nuclear engineering in the oil and gas extraction sector is significant and yields clear production benefits. In oil extraction, water is pumped into the field to maintain pressure and push oil toward the extraction wells. The efficiency of extraction largely depends on the effectiveness of water injection. Therefore, controlling the water injection process is a crucial task with significant economic and technical implications for extraction companies. The marking technique is almost the only method for experimental data on the movement of injected water in the field.

The initial success convinced management levels about the capabilities of the Vietnam Atomic Energy Institute and opened up prospects for a research direction applying radioactive isotopic techniques for industrial production, particularly in oil and gas extraction.

With state funding for research and support from the IAEA for basic equipment and specialists, a significant opportunity arose to develop a radioactive isotope marking method to survey the movement of injected water.

However, Vietnam’s oil fields primarily consist of fractured granite formations, with depths exceeding 4,000 meters, temperatures over 150°C, oil bodies hundreds, even thousands, of meters thick, and heterogeneous, complex permeable structures with unique characteristics that the world has little experience with. While the engineers and oil and gas scientists of Vietsovpetro pioneered the discovery of oil and gas potential in granite fields and developed appropriate extraction technology, those researching applicable technologies for these types of fields also needed to invest in understanding them to create suitable technologies.

After nearly 10 years of focusing on the application topic in granite fields, inheriting global experiences while learning and improving technologies, the Institute has developed its technology comprising six different tracers capable of withstanding high temperatures, along with suitable methods for pumping, sampling, and analyzing tracer enrichment. As a result, they won an international bid in 2004 for the Black Lion field against contractors from the UK, USA, and Norway, signing numerous contracts with domestic and international oil extraction companies, implementing this technology in fields like Rang Dong, Bach Ho, and Rong.

It is a point of pride to assert that this technology emerged at the right time, meeting the survey needs during extraction in fractured granite fields on Vietnam’s continental shelf. The next technology of Nguyễn Hữu Quang and his colleagues is to survey and assess residual oil reserves during extraction, which is a pressing need for production.

The oil and gas industry is a significant technical economic sector that demands very high technical standards, with harsh working conditions. From the laboratory, to provide high-tech services that meet the requirements of industrial production, especially in the oil and gas industry, nuclear application researchers have made great efforts to proactively organize work, overcome challenges, unite, and build a highly professional team.

Currently, they are urgently enhancing the laboratory’s capabilities according to global oil and gas standards, preparing for participation in international technical services, and expanding application markets in fields outside Vietnam in the near future.

The “Wellhead Sampling Machine” designed and manufactured by the Institute of Atomic Energy has achieved international DNV certification, receiving high praise from oil and gas companies and is planned for mass installation on offshore drilling rigs. Many oil and gas engineers take pride in this Made in Vietnam device, which, although small, is the first technological product of Vietnam associated with drilling equipment.

Not stopping there, with strong support from Vietnam, they are preparing for larger-scale research programs to establish new research directions serving the exploration and extraction of mineral resources and oil and gas in the country, actively preparing for service exports to the world.

To date, from a three-person laboratory, it has grown into the Nuclear Engineering Application Center in Industry with three specialized laboratories, researching and implementing nuclear engineering applications for diagnosing and optimizing industrial processes, contributing to a new research application direction – “Nuclear Engineering Applications in Industry” for the Da Lat Nuclear Research Institute and Vietnam’s atomic energy sector.

These technologies allow direct surveys of production lines and equipment without interrupting operations, serving various industries such as chemicals, oil refining, cement, oil and gas extraction, paper, industrial waste treatment, and transportation infrastructure.

In regional and international forums such as the Asia-Pacific Regional Cooperation Agreement (RCA) and the IAEA Joint Research Cooperation Program, the laboratory led by Nguyễn Hữu Quang has gained significant recognition and prestige, becoming a leading industrial application laboratory in the region.

Vietnam’s positive contributions and rapid advancements in this field have been highly regarded by international organizations such as RCA and IAEA, as well as laboratories worldwide. The Atomic Energy Institutes of countries in the region, such as Indonesia, Malaysia, Thailand, and Myanmar, have expressed interest in importing our technology under bilateral and multilateral cooperation programs. The dream of Nguyễn Hữu Quang has now become a reality.

HỒNG KIÊN