Piranha solution is a mixture typically composed of a 3:1 ratio of concentrated sulfuric acid (H2SO4) and 25-30% hydrogen peroxide (H2O2). Other ratios such as 4:1 or 7:1 can also be used. A similar solution, sometimes referred to as basic Piranha solution, consists of a 3:1 ratio of ammonium hydroxide (NH4OH) and 25-30% hydrogen peroxide.

Piranha solution is utilized for cleaning organic contaminants from the surfaces of substrates. As a strong oxidizing mixture, it can effectively remove most organic materials. Piranha solution is also occasionally employed for acid etching of titanium.

Piranha solution can explode if the concentration of hydrogen peroxide exceeds 50%.

When working with Piranha solution, it is essential to wear special protective equipment such as safety goggles, plastic gloves, lab coats, masks, and use laboratory equipment like fume hoods with airflow of 0.4 m/s or more.

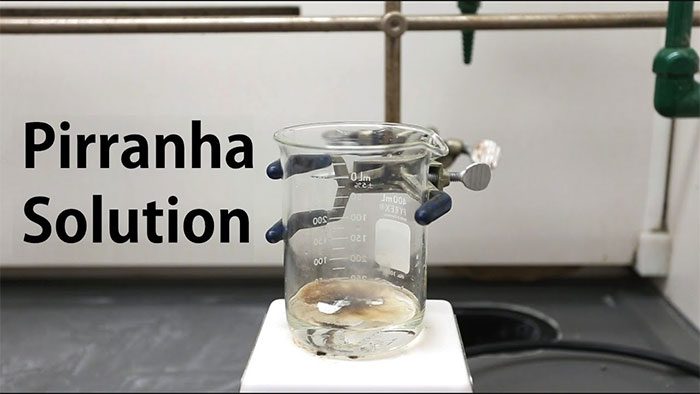

Piranha solution can be explosive if the concentration of hydrogen peroxide exceeds 50%. The freshly prepared mixture generates a significant amount of heat, reaching up to 120 °C for the acidic form and 60 °C for the basic form. When preparing the solution, hydrogen peroxide must be quickly poured into concentrated sulfuric acid[1], as an immediate exothermic reaction occurs, producing gas; the order of mixing must not be changed. This mixture should never be combined with organic substances such as acetone (CH3COCH3), isopropyl alcohol (C3H8O), nylon, etc., as this can lead to explosions.

The destructive power of Piranha solution.

During operations, carefully and slowly immerse materials with organic stains into the Piranha solution bath. Substrates should be thoroughly cleaned and dried before immersion. This solution should not be stored in tightly sealed containers, as the gas generated can cause the container to explode. It is recommended to keep it in a fume hood.

The Piranha solution should be used immediately after preparation. The heated solution will effectively clean organic stains from substrates, oxidizing and hydrolyzing most metal surfaces. The immersion time ranges from 10 to 40 minutes. After removing the substrate from the solution, rinse it thoroughly with deionized water (or distilled water). To avoid thermal shock that may break the substrate, immerse it slowly into the bath.

Let’s see how the iPhone 7 will turn out after TechRax’s experiment.