Associate Professor Dr. Huỳnh Trọng Phước (Can Tho University) participates in research on concrete-like materials from sludge waste and fly ash for use in land leveling.

Associate Professor Phước (35 years old) has recently been awarded the 2023 Golden Globe Award for excellence in scientific research and training, with the creation of materials from sludge waste being one of his notable projects.

Professor Phước mentioned that the research was conducted while he was pursuing his Ph.D. at the National Taiwan University of Science and Technology seven years ago. At that time, a wastewater treatment company in Taipei commissioned a study to utilize the existing settling sludge at the plant as material for internal land leveling within the facility.

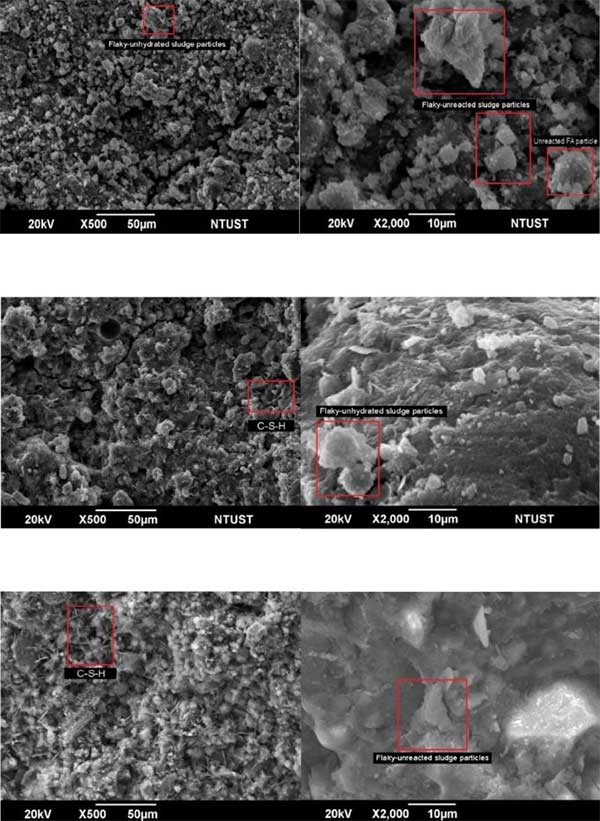

Dr. Phước and his research team developed a method of mixing settling sludge with fly ash along with a small amount of cement and other additives to create controlled low-strength material (CLSM). The addition of cement and additives provides an environment conducive for the fly ash and settling sludge to undergo chemical reactions, forming CLSM materials with load-bearing capacity.

Associate Professor Dr. Huỳnh Trọng Phước (second from the left) during his study and research period in Taiwan. (Photo: NVCC)

He explained that the settling sludge in the wastewater treatment plant contains a relatively high amount of silicon dioxide (SiO2) and aluminum oxide (Al2O3), which is similar to the composition of fly ash found in coal-fired thermal power plants. The specific gravity and particle composition of these two materials differ significantly, making them suitable for mixing to create CLSM. “Depending on the specific needs of the ordering entity, the proportions of each material component can be adjusted to achieve the desired product,” he said.

The research team established a procedure for producing CLSM using sludge and fly ash sourced directly from emission sources to the laboratory and used directly without extensive processing.

Professor Phước mentioned that depending on specific conditions, mixing can be done wet or dry (the materials must be dried before use). For the CLSM material intended for land leveling, the team chose the wet mixing method to save on processing costs.

Section for collecting sludge waste at the plant for research. (Photo: NVCC)

After several laboratory trials, evaluations, and adjustments, the team optimized the method to ensure the product meets usage requirements. This was also the most challenging and time-consuming step, requiring careful design and mixing calculations. The team had to conduct numerous trials because even small adjustments in component ratios could significantly change the product’s properties. Additionally, the mixing method and equipment used also greatly influenced the research results.

Comparing with traditional sand leveling materials, Professor Phước asserts that these are entirely different methods. When leveling with sand, the process typically relies on compaction energy to densify the material to a specified compactness for acceptance. In contrast, CLSM is a type of controlled low-strength material, akin to a concrete designed for various specific purposes, meaning it can be adjusted according to usage requirements. The higher the quality requirements, the greater the production costs will be.

While the material shows great potential for practical application in land leveling, Professor Phước believes that to be used on a large scale like traditional sand leveling materials, a thorough analysis of actual production costs and long-term environmental impact assessments are necessary. “There needs to be specific standards and regulations regarding technical requirements for construction and acceptance,” he stated. Furthermore, a stable source of sludge and fly ash needs to be ensured to provide a large enough supply for industrial-scale production to have practical application.

Microscopic image of CLSM material from the research group. (Photo: NVCC).

The research of the group has been highly regarded and has been implemented in a pilot land leveling project at a wastewater treatment plant in Taipei. Preliminary assessments right after implementation have demonstrated the high applicability of the designed material. The research team is currently monitoring and periodically sampling to observe the long-term performance of this material for optimizing design methods and construction measures regarding CLSM.

In Vietnam, there have been some studies applying fly ash and sludge waste as leveling materials, but they have not been widely published in scientific articles. For application in Vietnam, it is necessary to establish a set of technical standards as a basis for calculating material quotas, to be integrated into road construction projects using budget funds.

Furthermore, the raw material source must ensure stability and continuity to carry out large-scale projects. While fly ash can meet this requirement, according to Professor Phước, it is challenging to meet the need for sludge waste as wastewater treatment systems typically require 1-2 years before dredging occurs. He mentioned that this could be addressed by researching alternative resource usage to replace sludge waste or altering the mixing method to adjust material ratios while still meeting requirements. “There is currently a construction company preparing to propose a small-scale pilot project, followed by recommendations for establishing technical standards, assessing environmental impacts, and other procedures for widespread implementation,” Professor Phước stated.