Master Le Ngoc Hanh Researches Mud-Free Eel Farming Technology in Closed Recirculating Systems, Shortening Farming Time by 2 Months.

In 2011, Master Hanh from the Aquaculture Research Institute 2 participated in a catfish farming project using recirculating technology funded by Wageningen University in the Netherlands. Over three years of implementation, he contemplated applying the principles of recirculation to other aquatic species such as eels and crabs. In 2014, he developed a mud-free eel farming process using a closed recirculation system, employing water treatment systems to create the best environment for eels to grow rapidly.

The system consists of a breeding tank with an area of approximately 4m2 (2m in diameter), designed in a rounded square shape to ensure effective water circulation across the surface and maximize the farming area. The tank also includes substrates like nets and plastic fibers to provide eels with a place to hide and surface for breathing.

The water treatment system includes mechanical filtration and biofiltration, which help remove waste and excess food from the water. Toxic gases dissolved in the water are biologically treated using substrates. The recirculating system is equipped with auxiliary devices that supply oxygen, sterilize using UV light, and decolorize with sand, helping to keep the water clearer.

Eels grow after one month using mud-free farming technology with a recirculating system at the experimental farm of the Agricultural Extension Center in Tien Giang. (Video: NVCC)

According to Master Hanh, traditional eel farming requires water changes 1-2 times daily. In contrast, recirculating eel farming does not require this throughout the farming process. Farmers only need to add a small amount of water to compensate for evaporation or leaks. This saves a significant amount of water each farming cycle and reduces labor costs.

Additionally, the recirculating system ensures a cleaner living environment for the eels, providing higher stability compared to water replacement methods. This is because changing the water disrupts the eels’ living environment, affecting their growth potential. “Water replacement methods can take 10-15 months to harvest. Recirculating technology only requires 8-10 months,” said Hanh. Furthermore, farmers currently primarily use well water for eel farming, which may contain residual toxic substances if not treated, affecting the growth rate of the eels.

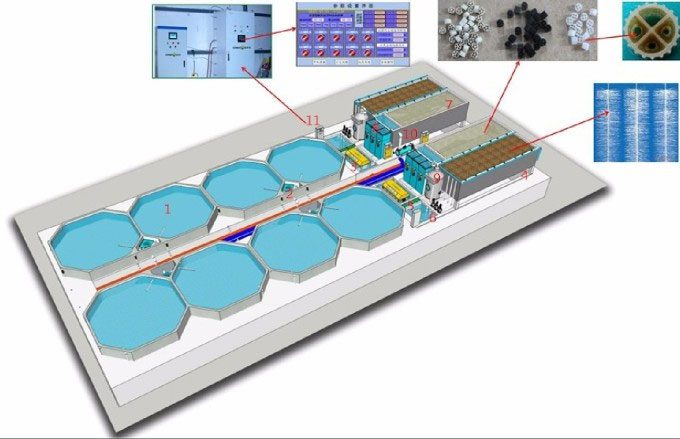

Operational diagram of the 8 tank model. (Photo: NVCC)

Using filtration, oxygen supply, and sterilization systems means that the recirculating technology consumes about three times more electricity than traditional water replacement eel farming. However, Master Hanh stated that this technology allows for a maximum density increase of up to five times in the same area, and the reduced farming time can offset the electricity costs.

The standard tank design has a diameter of about 2 meters with an area of approximately 4 m2. Each tank can accommodate 2,000 juvenile eels (around 500 eels per m2), yielding 400-500 kg of marketable eels, with the potential to increase density for higher productivity.

The profit margin for eel farming is estimated at 20%, meaning that for every kg of eel with an investment cost of about 100,000 VND, the selling price averages about 120,000 VND. The investment cost for the recirculating equipment for a 5-ton farming scale is around 400 million VND. At this scale, farmers can earn a profit of approximately 100 million VND per cycle. Thus, farming 3-4 cycles could recover the investment without considering the cost of juvenile eels. “This is not a quick wealth solution, but this technology is sustainable and suitable for urban agriculture, which is limited in space and clean water resources,” Hanh stated.

Mechanical filtration device of the system. (Photo: NVCC)

In March 2021, the mud-free eel farming model in a recirculating tank was tested at the Agricultural Extension Center in Tien Giang, with a scale of 4 tanks each approximately 4.8 m2. The experimental model was tested with various densities to assess performance, achieving an average yield of 50 kg of eels per m2.

According to Mr. Nguyen Tan Quoc, Director of the Center, the trial farming process achieved initial effectiveness with no need for water changes while eels still grew well, showing rapid growth in the first month. “With this model, the investment cost is not too high, but it can create livelihoods for people who do not have access to large spaces or live in areas with limited access to clean water,” Mr. Quoc stated.