The RMIT University research team is processing medical mask waste combined with recycled concrete aggregate to create materials for road layers.

The recycling method used by the research team aims to utilize the large amount of single-use medical masks released into the environment daily due to the Covid-19 pandemic.

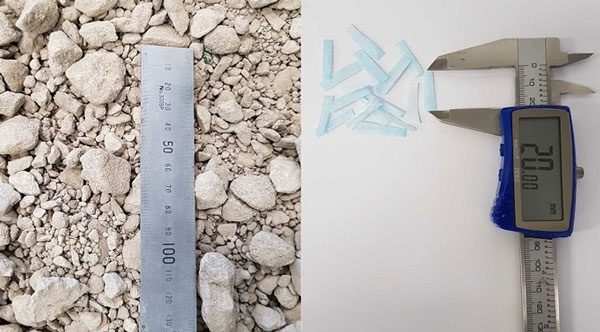

After being collected and disinfected, the masks are cut into small pieces measuring 2 cm to be combined with materials for the upper and lower base layers. The mask fragments are ground into powder to be used as asphalt material.

The raw materials are then heated to 75 degrees Celsius. This step also ensures that the materials are completely free of bacteria while assessing the elongation and tensile strength when exposed to high heat. Dr. Mohammad Saberian, a member of the research team, stated that the heating process helps improve the elongation of the material by up to 118.91%.

The used construction mortar is processed into recycled concrete aggregate consisting of stones, bricks, and concrete, with appropriate fineness and sand content. The recycled aggregate is then mixed with the treated mask material. The research team conducts tests to determine the appropriate mixing ratio between the two components.

By gradually increasing each ratio, the mask material content is determined to be at 1%, while the recycled aggregate accounts for 99%. This mixture maintains a good bond between the two materials through tests on pressure, strength, deformation, and dynamic properties, meeting the relevant construction technical specifications.

The final product made from two recycled materials. Photo: RMIT.

“The 1% ratio of recycled mask fragments in the mixture may be small, but it has the highest elastic value when combined with the concrete aggregate,” Dr. Mohammad Saberian told VnExpress. He noted that adding masks to the recycled concrete aggregate helps reinforce the material layer while addressing medical waste and construction waste. However, too high a ratio of mask fragments could affect the durability and elasticity of the road layers.

“This method is not only significant for recycling medical waste that pollutes the environment but also provides real technical benefits,” Dr. Mohammad Saberian stated.

The road consists of four layers: the bottom base layer, the upper base layer, the lower base layer, and the top asphalt layer. These layers must be sufficiently rigid and crack-resistant to withstand the pressure from heavy trucks. Therefore, the processing of mask materials must ensure a certain level of fineness and porosity.

Recycled concrete aggregate (left) and mask fragments mixed for recycling. Photo: RMIT.

The research team also pointed out that a 1 km stretch of two-lane road made from materials combined with recycled masks would require three million used masks, effectively addressing a large amount of mask waste released into the environment.

Currently, the team continues to improve the parameters of the mixture to create a complete prototype road section. Scientists will explore the potential of medical masks in the production of recycled concrete and asphalt. In addition to masks, some personal protective equipment is being evaluated by the team for its suitability for recycling using this method.