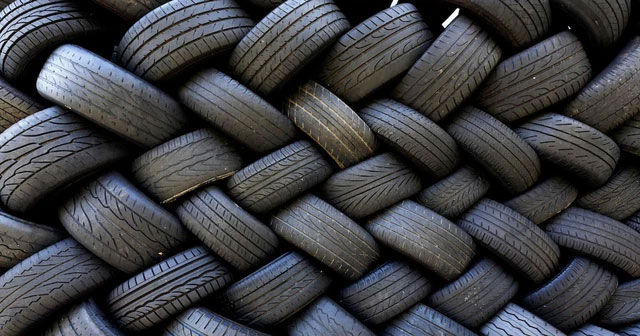

Every year, more than 300 million scrap tires are generated in the United States alone. These tires are rarely recycled due to their characteristics, which means they often end up in landfills, potentially causing serious fire hazards over time.

Therefore, finding solutions to recycle tires easily and effectively is a significant challenge, but it also presents an opportunity for research and the discovery of advanced scientific methods.

Researchers at the University of South Australia and RMIT University have been working towards this goal in recent years by grinding old tires into fine particles for use in concrete production. According to their research findings, concrete slabs made using these recycled tires have proven to be economically viable and even more durable than conventional concrete in real-world conditions.

The number of discarded tires globally continues to rise, with estimates from the European Union suggesting that this figure could reach 1 billion tires annually. Used tires create waste that negatively impacts the environment. Currently, tire disposal mainly involves highly polluting methods (e.g., incineration to produce fuel oil), with only a small portion of these tires being recycled scientifically, such as producing rubber powder.

By recycling old tires as building materials, researchers aim not only to address part of the tire landfill issue but also to mitigate the environmental damage caused by the concrete industry—one of the highest carbon-emitting sectors globally, accounting for 9% of total CO2 emissions worldwide in 2018.

The formula for creating this super concrete is actually quite simple (though the scientists did not disclose specific details). You just need to mix aggregates with cement and water in appropriate amounts. This formula will vary depending on the type of structure and construction purpose.

Rubber mixed with concrete is typically recycled black rubber powder from tires, representing one of the advanced applications in construction, providing long-lasting durability to concrete and reducing cracking during use. Recycling scrap tires is crucial for environmental protection and economic benefits.

To support their research, Australian scientists replaced up to 20% of sand with shredded rubber to create concrete slabs both in laboratories and residential areas. Two reinforced rubber concrete slabs were then placed on the campus of the University of South Australia and part of the entrance to one of the civil engineering laboratories, a high-traffic area in 2018. At the same time, they placed two identical slabs made from conventional concrete alongside for comparison.

According to Dr. Osama Youssf, one of the co-authors of the study, reinforced shredded rubber concrete outperforms conventional concrete in several metrics, including impact resistance, durability, flexibility, thermal insulation, sound insulation, and weight (the rubber slabs are lighter than traditional concrete).

In practice, this super concrete is considered one of the groundbreaking products in concrete technology, exhibiting excellent properties such as high flowability, high compressive strength, and outstanding durability. Conventional concrete production emits a significant amount of carbon, so when it begins to crack, degrade, or fail, and structures need to be replaced, it adds further pressure on the environment. “The results clearly show that shredded rubber concrete is a viable and promising alternative to traditional concrete in the housing market. We strongly encourage the concrete industry to consider shredded rubber concrete as a sustainable alternative to traditional types in construction projects in Australia,” said Professor Yan Zhuge, a member of the research team.

“For pumping, screeding, or finishing the surface of the concrete with a power trowel, contractors also reported no differences between using shredded rubber concrete and conventional concrete; however, the rubber mix requires less physical effort in all aspects,” Youssf noted. “Additionally, ready-mix concrete companies reported no concerns regarding the mixing process or transporting the concrete, and cleaning concrete truck mixers is much easier.”

This is fantastic news for the construction industry; this research indicates that shredded rubber is an excellent alternative to the types of aggregates commonly used in conventional concrete. In another development, American researchers at North Dakota State University have used shredded rubber from old tires to create rubberized asphalt, and their research results also indicate it is very sturdy and useful.