The HEAP Robot Uses Advanced Technologies to Scan, Classify Rocks and Recycled Materials, and Then Automatically Build Walls.

A research team led by Ryan Luke Johns, an expert at the Swiss Federal Institute of Technology Zurich (ETH Zurich), has developed a 12-ton automatic robot capable of constructing stone walls from natural and recycled materials. The new research was published in the journal Science Robotics on November 22.

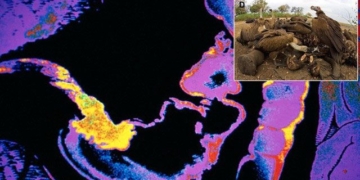

The HEAP Robot builds a self-standing wall from recycled concrete and gneiss rock. (Photo: Michael Lyrenmann/Science Robotics).

The robot, named Hydraulic Excavator for Automation Purposes (HEAP), utilizes advanced technologies such as LiDAR (Light Detection and Ranging), image segmentation, and planning algorithms. It can efficiently and environmentally friendly scan, classify, and stack rock blocks and concrete blocks.

The new robot has been tested at two locations. It can construct a self-standing wall 10 meters long and a 65-meter long earth-retaining wall, using only materials available at those sites. The robot also establishes a 3D digital repository that stores the materials, making it easy to reuse and recycle them when the wall is no longer needed.

The research team stated that HEAP could help address the challenges facing the construction industry, which accounts for over 10% of the world’s GDP but suffers from issues such as low productivity, high waste, and labor shortages. By using robots to build with recycled materials, natural materials available locally, and consuming less energy, the construction industry can reduce its environmental impact, increase efficiency, and enhance sustainability.

The research team also confirmed that HEAP can reduce CO2 emissions by up to 41% compared to constructing a traditional reinforced concrete wall. They noted that the new robot is a testament to a future of robotic construction, where machines can work autonomously and collaborate to create flexible, adaptive structures.