The traditional production technology of Portland cement still has drawbacks, leading to significant greenhouse gas emissions due to the raw materials being subjected to high-temperature firing. To address this, many modern technologies have emerged, the latest of which is a biotechnology recently unveiled.

Biotechnology using waste materials, primarily two main raw materials: industrial carbide sludge and urea. (Illustrative image).

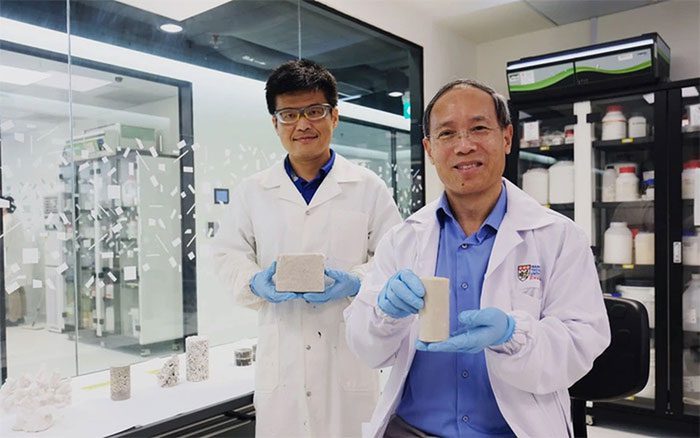

This technology was developed by Nanyang Technological University in Singapore. It utilizes waste materials, primarily two main raw materials: industrial carbide sludge, a byproduct from the production of acetylene gas, and urea, which is derived from the urine of mammals such as cows or pigs…

The sludge is pre-treated with acid to produce soluble calcium. Then, urine is added to form a cement solution. Special bacteria are subsequently introduced into this solution, tasked with breaking down urea to form carbonate ions. The next step, in a process known as “microbially induced calcite precipitation”, involves the carbonate ions reacting with dissolved calcium ions to form hardened calcium carbonate.

When the mixture is combined with sand or soil, a reaction occurs where calcium carbonate bonds with the sand and fills the voids in the material. As a result, a solid material resembling concrete is created, which is waterproof and has a color similar to the original sand or soil.