Scientists have successfully simulated the tooth formation process of sea stars and applied this knowledge to create durable materials comparable to carbon fibers that are also biodegradable.

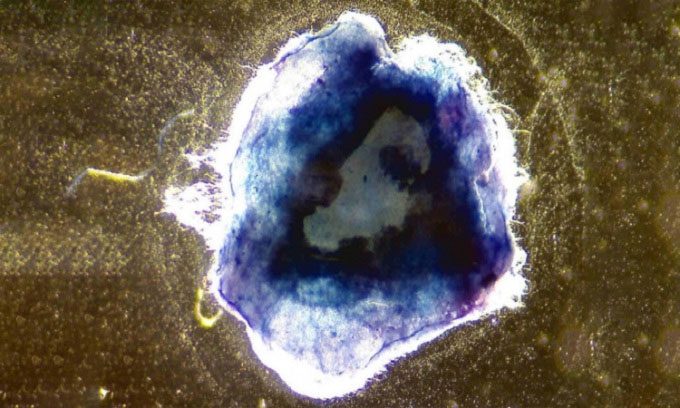

Biomaterial inspired by sea stars dyed blue in the laboratory. (Photo: University of Portsmouth)

A study published on July 7 in the journal Nature Communications reveals that the new biomaterial can be enhanced to become super durable, matching the strength and flexibility of synthetic materials without producing toxic waste. “Synthetic materials like Kevlar are widely used, but their production can be hazardous, and recycling is often difficult and costly. The material we have created here is much more sustainable in terms of sourcing and production processes, and it can biodegrade at the end of its life cycle,” said Robin Rumney, the lead researcher from the School of Pharmacy and Biomedical Sciences at the University of Portsmouth.

In 2015, researchers discovered that the most durable biomaterial in the world comes from sea stars, marine mollusks with conical shells that typically cling to rocks. They use a tongue covered with tiny teeth to scrape food off rocks and into their mouths. These teeth contain a hard yet flexible compound that is significantly stronger than spider silk and can rival synthetic materials, including carbon fibers and Kevlar.

The extreme durability of sea star teeth results from a unique structure containing chitin fibers combined with fine goethite crystals, a type of iron-containing mineral. These fibers interweave in a manner similar to carbon fibers used to reinforce plastics.

To develop the material, the research team devised a method to precipitate chitin and iron oxide on serum-coated glass, mimicking the process found in sea star teeth. After two weeks, the compounds spontaneously formed a structure similar to a part of the sea star known as the Aristotle’s lantern, which then developed into teeth. Rumney took six months to design this process.

After successfully simulating the tooth formation process of sea stars, the research team was able to produce a sample of the biomaterial measuring 0.5 cm wide by mineralizing chitin. Next, Rumney and colleagues will explore the potential to scale up these small disks and mass-produce them, thereby replacing the use of plastics with non-toxic biodegradable products.