Experts Seek to Distill Whiskey in Shorter Time Instead of Aging for Years in Oak Barrels

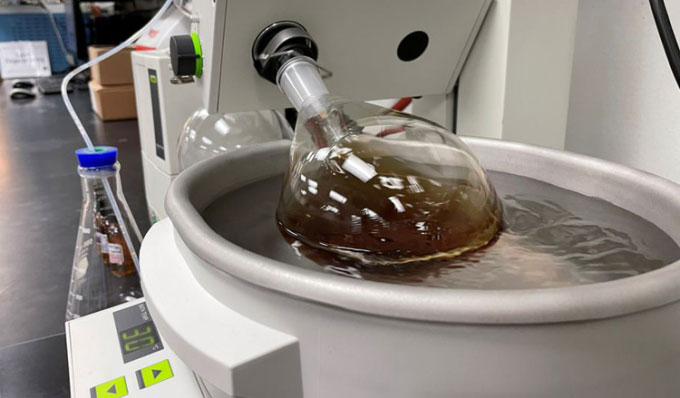

Bespoken Spirits whiskey sample during the removal of certain chemical compounds in the laboratory in California on December 7. (Photo: Reuters/Nathan Frandino).

In a small laboratory in Silicon Valley, California, experts from Bespoken Spirits are producing whiskey. However, the room is devoid of the towering stacks of oak barrels typically found in traditional distilleries, and there is hardly any wood in sight. Instead, they utilize syringes, cups, and test tubes to develop a more sustainable method of whiskey distillation.

Whiskey is usually aged in oak barrels for 5 years, with some varieties even aged for over 30 years. However, Bespoken Spirits employs new technology to extract the essential elements from oak barrels that enhance aroma, color, and flavor in a much shorter timeframe.

The whiskey is stored in metal containers for about 3 to 5 days. This innovative technology accelerates the oxidation process, thereby altering the whiskey’s flavor using just a piece of oak the size of a pinky finger. Specifically, the experts char the oak wood in the laboratory and cut it into tiny pieces that are about 1/25,000 the size of a traditional barrel. According to materials scientist Martin Janousek, co-founder of Bespoken Spirits, this approach allows them to reduce wood usage by up to 97%.

By eliminating the need for oak barrels, Bespoken Spirits can avoid deforestation while also reducing the costs associated with barrel storage over many years. “Today’s consumers tend to be more concerned about factors like climate change,” shared Stu Aaron, co-founder of Bespoken Spirits, with Reuters on December 9.

Due to the short aging process, the whiskey does not lose liquid through evaporation, which helps reduce water usage by approximately 20%, according to Aaron. Additionally, the new technology enables experts to customize various flavors for the whiskey.