Thomas Edison’s Dream of Mass-Producing Affordable Homes with a Single Pour of Concrete

At the end of the 19th century, like many entrepreneurs and builders of his time, Thomas Edison was captivated by the potential of concrete. He believed that concrete was the future and the solution to all housing problems.

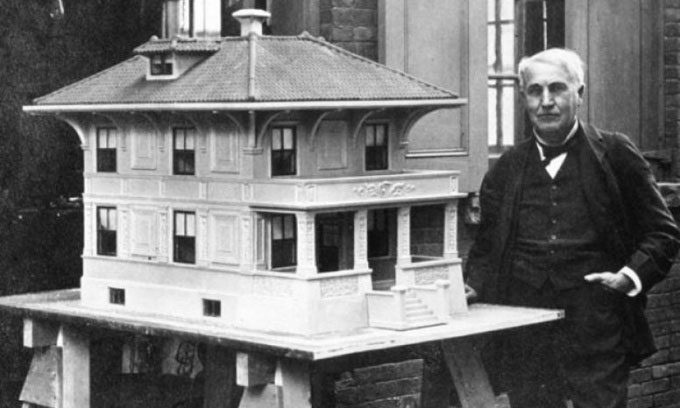

Thomas Edison presents a model of a concrete house. (Photo: Amusing Planet).

However, Edison’s foray into the cement industry was somewhat accidental. For ten years, he unsuccessfully crushed iron ore and sold the waste powder from his milling operation to cement manufacturers. Faced with stiff competition from ore mills in the Midwest, Edison sought to keep his mill operational using funds from his highly successful company, General Electric. Realizing he was trying to achieve the impossible, he decided to pivot to cement production, utilizing the very waste he was selling to his competitors.

In 1899, Edison founded the Portland Edison Cement Company and constructed a massive plant in western New Jersey, featuring rotary kilns that were 46 meters long, the largest in the world at that time. Within a decade, the company became the fifth-largest cement producer globally. Edison’s research team continually improved the cement production process, and he relentlessly filed patents for these innovations. In total, Edison held 49 patents related to cement production.

He patented a method for casting houses with a single continuous pour, rather than pouring one floor at a time. Beyond walls and floors, Edison envisioned that every structure inside — bathtubs, toilets, sinks, cabinets, beds, refrigerators, pianos — would also be made from concrete.

“The purpose of my invention is to construct a building from a mixture of cement with a single continuous pour. Every part of the structure, including walls, roofs, partitions, bathtubs, floors… is created from a single block of cement mixture. This invention could be applied to all types of structures, but I intend to specialize in residential buildings, where stairs, fireplace facades, decorative ceilings, and other interior details can be produced in one solid pour. A house built this way would be nearly indestructible,” Edison wrote in his patent application.

Concrete homes in Gary, Indiana, USA, built using methods developed by Thomas Edison. (Photo: Eric Allix Rogers/Flickr).

To prove the feasibility of this idea, Edison poured concrete for two test structures — a gardener’s house and a garage — at his Glenmont estate in New Jersey in 1910. He later announced he would give the patent information to qualified builders instead of trying to profit from it.

This statement caught the attention of philanthropist Henry Phipps Jr., who proposed using concrete houses to address New York City’s housing crisis. Phipps claimed he would build an entire city for working families using Edison’s concrete casting technique.

However, when it came time to implement, Edison realized his dream was unachievable. One of the main technical challenges of single-pour concrete houses was the complexity of the molds. Each house required over 2,000 precisely placed mold pieces, which then had to be carefully dismantled and reassembled for the next house. This process was too cumbersome and complex, not to mention the high costs for contractors. Another issue was the pouring process. Edison’s engineering team faced the challenge of creating a mixture that was fluid enough to flow into every nook and cranny of the mold, yet thick enough to keep the aggregate particles suspended in the mixture, preventing them from settling to the bottom due to gravity.

Ultimately, the Portland Edison Cement Company closed down in the 1920s. Despite seemingly insurmountable challenges, Edison managed to construct a few concrete houses in Union and Montclair, New Jersey, where they still stand today.