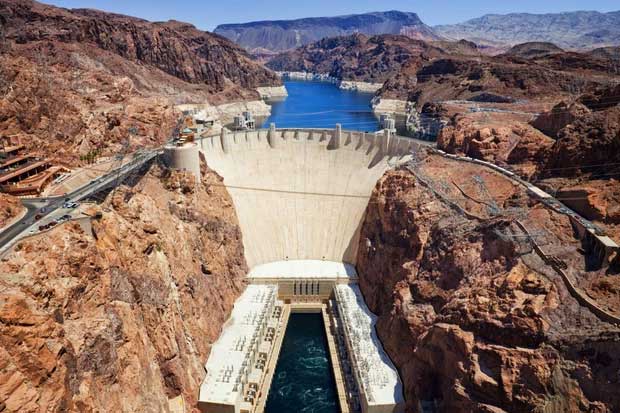

The Hoover Dam is among the most significant engineering projects in the United States during the 20th century. However, achieving this monumental feat came at a steep price.

Above the Black Canyon in Nevada, a group of workers hung precariously on the cliffside, secured by ropes tied around their waists.

Suddenly, one worker stepped too close to the edge. The ground gave way beneath him, and he plummeted into the abyss at a speed so rapid that no one had time to react. Fortunately, another worker, positioned further back, quickly lunged away from the wall, caught the falling man, and managed to pull him back to safety.

The man who was saved was an engineer. After rescuing him, the worker returned to continue his tasks.

And that was just another ordinary day in this canyon during the construction of the Hoover Dam—one of the seven great engineering projects in American history—at the beginning of the 20th century.

Hoover Dam is among the top 7 greatest engineering feats in American history

The Genesis of a Giant Dam

In the early 20th century, the United States began to expand its development across both coasts. A significant issue arose: many major cities in the arid Southwest lacked a reliable water supply.

While the Colorado River had been diverted through numerous canals, its unpredictable flow often led to flooding, jeopardizing agriculture. At the same time, cities and industrial areas in the Southwest were growing rapidly, meaning they required more energy than ever.

The beginning of the Hoover Dam construction plan

To address this issue, the U.S. Bureau of Reclamation proposed a solution in 1922: the construction of a massive hydroelectric dam, with the agreement of seven states surrounding the Colorado River. They all concurred that Black Canyon was the most suitable location for an arch dam.

An arch dam is a curved structure built upstream, utilizing the force of water to exert lateral pressure against the canyon walls, providing stability. While arch dams had been constructed in several ancient civilizations, the scale at Black Canyon was unprecedented at that time. The dam was planned to stand 221 meters high and span 379 meters across.

A Cost of Blood and Sweat

Building a dam of such magnitude required a massive workforce. However, due to the Great Depression occurring just a year after the project was approved, thousands flocked to apply for jobs on the project.

The earliest arrivals set up camp near the site, creating a makeshift village known as Ragtown. Lacking basic facilities and necessities, many suffered from heat-related illnesses during the scorching summer months. The U.S. government eventually decided to construct the town of Boulder, equipped with modern amenities and a hospital, to support the workforce for their critical project.

The first applicants turned out to be the most unfortunate

Before construction could begin, the Colorado River had to be diverted. Workers blasted both sides of the canyon and installed massive pipes totaling 5 kilometers in length, capable of transporting 5,600 cubic meters of water per second. However, to ensure the pipes were installed on time, workers faced immense pressure and endured harsh conditions. Temperatures in the tunnels were so extreme that many workers collapsed.

By fall 1932, the river was successfully diverted, but this led workers to confront even more dangerous tasks ahead. Their goal now was to blast and clear approximately 1 million cubic meters of rock from the canyon walls.

Foremen gathered workers experienced in high-altitude tasks, requiring them to secure ropes and lower themselves down the cliffs to drill rock and set explosives. From circus performers to sailors, and even locals, they volunteered (for the pay) to undertake this perilous work.

Workers were required to secure ropes and drill rock using tools and explosives.

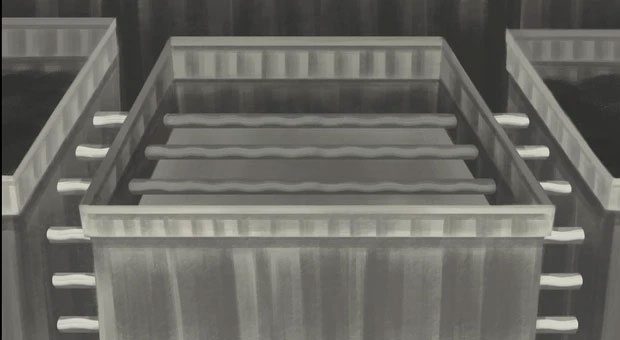

Once the rock walls were cleared, construction of the dam officially commenced. They needed to pour approximately 6.6 million tons of concrete—enough to pave a road across the United States. However, pouring such a colossal amount of concrete all at once would take over 125 years to cool and harden. To expedite the process, they poured the concrete into smaller sections, each equipped with cooling pipes running through them.

Concrete was poured into smaller sections, with cooling pipes running through to accelerate the cooling process

By 1935, nearly the entire dam was completed, two years ahead of schedule. On February 1, 1935, the diversion tunnels were opened to allow water to flow into the dam’s reservoir, which could hold more than twice the annual flow of the Colorado River. At that time, the dam was the tallest man-made structure in the world, a proud milestone in the nation’s history.

Over 100 people died during the construction of the Hoover Dam.

However, the rapid pace of construction came at a significant cost. The project employed 21,000 workers due to the impact of the Great Depression, and over 100 individuals lost their lives during its construction. Additionally, the creation of the reservoir displaced numerous communities and devastated the ecosystem surrounding the Colorado River.

Today, the Hoover Dam generates 4 billion kWh annually, providing electricity for 1.3 million residents. Yet, the consequences of the dam’s construction remain an indelible mark for those who study its history.