Saif Khawaja and a team of research engineers from Shinkei Systems have invented a superior fish catching and processing machine compared to traditional methods, saving time and ensuring nutritional content…

Fresh fish found in stores or supermarkets are often not as “fresh” as we might imagine, even when they are caught directly from fishing boats, according to observers. The way they are caught and killed is not only inhumane but also diminishes the nutritional quality of the meat.

Recognizing this issue, Shinkei Systems, based in Philadelphia, USA, has developed a superior alternative to conventional fish catching methods. Initially, this machine operated rather slowly and manually; however, the company has since automated the process. Shinkei Systems successfully raised $1.3 million to launch this invention into the market.

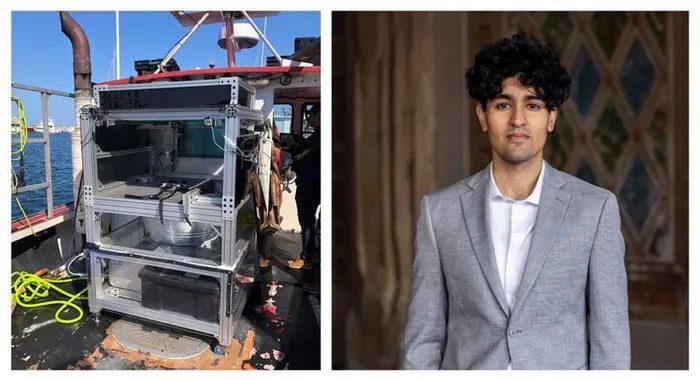

A Shinkei machine on a fishing boat (left). Engineer and co-founder of Shinkei Systems, Saif Khawaja (right).

Seeking a “Humane Death” Solution for Fish

Fishermen have never considered the so-called “humane” or “gentle” death for fish. This is nearly impossible, especially in large-scale fishing operations. Typically, fish are thrown out of nets and undergo preliminary sorting before being tossed onto ice. They struggle for a few minutes and ultimately suffocate within moments.

This method of catching fish is not only brutal but also causes the quality of the fish to deteriorate rapidly. Bacteria easily invade wounds, blood, and reduce the amount of lactic acid present in the fish’s flesh.

On the other hand, if fish are caught individually, fishermen must ensure that the fish remain alive or process them immediately to preserve their delicious flavor. Usually, fishers will apply a strong force to the fish’s head to stun them, preventing further struggle, before methodically gutting and cleaning the fish.

There is a better method than the two mentioned above, originating from traditional Japanese fishing techniques known as “ike-jime.” By following this method, the fish’s flesh is preserved well, allowing it to last several days or even weeks while retaining its flavor. Importantly, ike-jime also requires a high level of artistry.

Using the ike-jime method, the fish’s brain is first pierced with a sharp spike to quickly send them to the afterlife, followed by swiftly removing the fresh blood from the fish’s body and destroying the spinal cord. Although this process may seem horrific, it maximally prevents agonizing pain and the spread of bacteria and harmful substances into the fish’s body. The ike-jime method must be performed accurately immediately after catching the fish.

Shinkei Systems has automated the entire process after learning from this unique fishing technique. A team led by co-founder Saif Khawaja has invented a mechanical device to perform the ike-jime process directly on fishing boats within 10-15 seconds.

Operational Differences

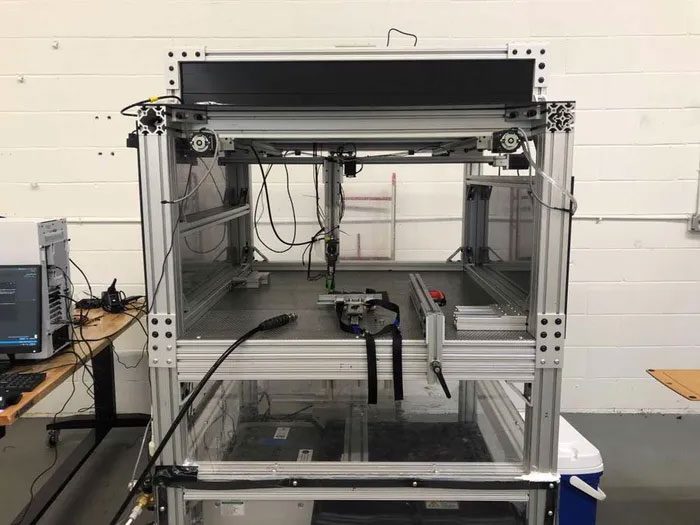

This fish catching machine is the size of a large refrigerator, featuring a large funnel to hold the fish, a mechanism to perform the ike-jime process, and an output for the cleaned fish to be placed into an ice water tank. The computer system identifies the species and shape of the fish in the funnel, pinpointing the location of the brain and other vital parts.

“Our vision is to automate the entire process without the need for a human operator,” Khawaja said. The machine can also operate even when the fishing boat is tilted due to large waves. Additionally, the brain location identification is highly accurate and adaptable to all types of fish.

A close-up of Shinkei Systems’ fish catching and processing machine.

This startup idea has never been launched or implemented in Silicon Valley. “Currently, we are working with fishermen in Maine, New Hampshire, and Cape Cod, while collaborating with distributors for major restaurants in Manhattan,” Khawaja added.

This machine has brought substantial profits to Shinkei and its partners. Restaurants are willing to pay a premium for fish processed using the ike-jime method because they are tastier and have a longer shelf life. The question remains, can fish processed by Shinkei’s machine compete with those processed by hand?

Khawaja recounts: “We had a rather interesting experience. We delivered fish to the sous-chef of a world-renowned restaurant. I presented him with three boxes of fish: one box contained fish that suffocated from being processed using conventional methods, another box had fish processed by the traditional ike-jime method (done by hand), and the last box was processed by our machine. Of course, the fish caught by conventional methods were easily recognizable, but he could not distinguish between the two remaining boxes of fish. Only sushi chefs could do that!”

The ike-jime method is gaining support from many, prompting Shinkei to aim to expedite the launch of its products into the market. Their machine will help fishermen catch fish faster and in greater quantities, simplify the processing procedure, and yield higher profits.

“Shinkei raised $1.3 million in its first seed funding round in January this year and is continuing to seek investment sources after conducting initial trials and modifying the design. Shinkei hopes that its invention will reach every fisherman and contribute to creating delicious fish dishes in the near future,” Khawaja affirmed.