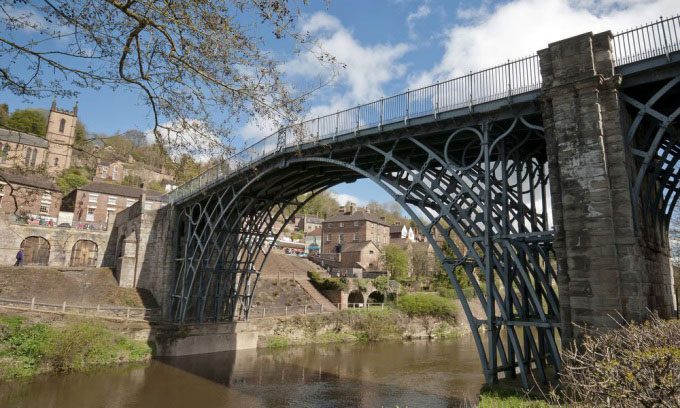

The Iron Bridge, the world’s first large cast-iron bridge, was completed in 1779 and still stands strong over the River Severn in Shropshire, England.

Cast iron is an alloy of iron and carbon, used since ancient times to create pots, pans, cannonballs, and decorative items such as window grilles and fireplace fronts. However, this material had never been employed for structural purposes until architect Thomas Farnolls Pritchard proposed the construction of the Iron Bridge using cast iron in the Severn Gorge, Shropshire, England.

Iron Bridge spanning the River Severn. (Photo: Bs0u10e0/Flickr).

The Severn Gorge, later renamed Ironbridge Gorge after the bridge, is rich in coal, iron ore, and limestone. The industry extracting these resources also thrived in the area by the late 18th century.

As industry progressed, the demand for a durable bridge to transport goods across the river emerged. Given the steep gorge and unstable riverbanks, the bridge needed a single span and sufficient height for boats to pass underneath. The river below was also an important trade route.

The only acceptable material was cast iron; however, no one had ever built a large-scale bridge of this material before. The Iron Bridge was the first of its kind, although it was not the first bridge made of iron. In 1755, an iron bridge was constructed in Lyons, but it was later abandoned due to cost issues. In 1769, a 22-meter wrought iron bridge was built across a waterway in Kirklees, Yorkshire.

Architect Thomas Farnolls Pritchard proposed a cast iron bridge connecting Madley and Benthall across the River Severn. Pritchard’s designs were approved, and construction began in 1777.

Abraham Darby III, an ironmaster in Coalbrookdale, was tasked with casting and constructing the bridge. Pritchard passed away just one month after the project commenced, and responsibility for the project shifted to Darby.

Darby cast all the necessary parts for the bridge—over 1,700 components, with the heaviest part weighing 5 tons—at his workshop. Each part was cast separately for assembly. He borrowed techniques from woodworking, adapting them for the properties of cast iron.

The Iron Bridge under construction by Elias Martin in July 1779. (Photo: Amusing Planet).

When completed in 1779, the Iron Bridge spanned over 30 meters and weighed nearly 400 tons. However, there are no authenticated documents or eyewitness accounts describing exactly how Darby lifted the iron blocks and positioned them across the river. In 1997, a small watercolor sketch by painter Elias Martin was discovered in a museum in Stockholm.

The painting depicts a movable wooden scaffolding. The scaffolding consisted of multiple piles driven into the riverbed and was used as a crane to position the bridge components. These parts were transported to the site by boat from Darby’s workshop, located 500 meters away. To confirm the reliability of the technical solution depicted in the painting, a large replica bridge, half the size of the original, was constructed in 2001 as part of a BBC study.

The success of the Iron Bridge inspired widespread use of cast iron as a structural material in Europe and America, despite cast iron being brittle and having low tensile strength. In the 19th century, many cast iron bridges experienced serious failures, the most famous being the Tay Bridge disaster in Scotland in 1879, which claimed 75 lives.

In 1943, the Iron Bridge ceased allowing vehicular traffic to prevent unnecessary stress on the structure and reduce the risk of collapse. That same year, the bridge was designated a historic monument in England. In the following decades, the Iron Bridge was reinforced with additional concrete supports. Today, the bridge stands as one of the iconic symbols of the Industrial Revolution.