Japanese scientists have recently discovered a method for creating self-healing plastic at room temperature, which can be used to manufacture smartphone screens and other products.

Previously, in 2018, Professor Takuzo Aida from the University of Tokyo and his colleagues utilized a substance known as “polyether thiourea” to develop a plastic material that can self-heal when broken pieces are reassembled at room temperature.

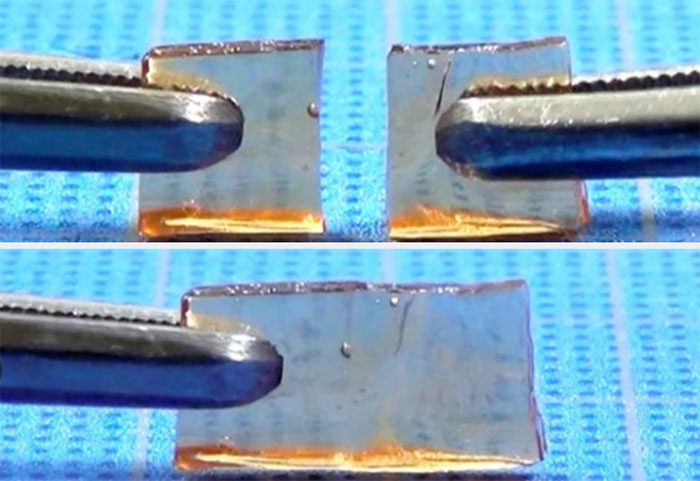

According to the research team, the new plastic can heal cracks in plastic products that are not visible to the naked eye – (Photo: Asahi.com).

In their latest research, they mixed this self-healing plastic with another type of plastic that does not have self-healing properties at a ratio of 20%. The research results indicated that this plastic mixture still retains its self-healing ability at room temperature.

Explaining the mechanism behind the new plastic, Professor Aida stated that the plastic contains twisted molecular chains. The bonds between these molecules disappear when the plastic product is cracked.

Currently, people need to melt conventional plastics at high temperatures to restore the bonds between these molecules. However, the new plastic can heal broken molecular chains through a mechanism known as “hydrogen bonding”. Therefore, reassembling the broken pieces at room temperature for about one hour allows them to fully restore the integrity of the bonds.

The research team noted that this new plastic can heal cracks in plastic products that are not visible to the naked eye. As a result, this technique could help develop sustainable plastic products that do not need to be discarded or recycled.

Scientists hope to apply this plastic in the production of mobile phone screens, eyeglass frames, household electronics, furniture, aircraft, and automobiles.