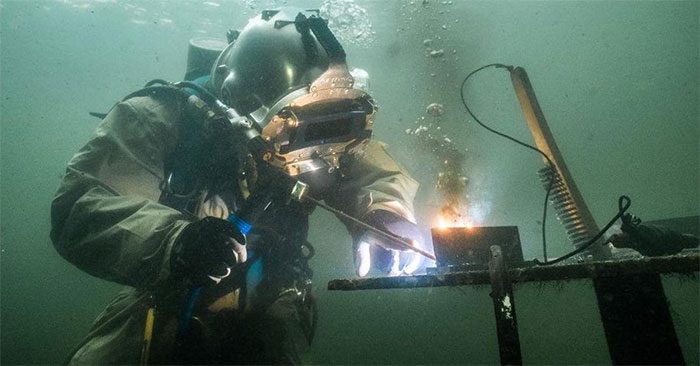

Compared to land-based welders, underwater welders face numerous unexpected dangers. Each year, globally, out of every 200 underwater welders, 30 lose their lives. Most of these fatalities stem from various causes such as electric shock, explosions, and illnesses.

The profession of underwater welding is considered extremely hazardous. However, it is essential for maintaining the integrity of bridges, preventing oil pipeline leaks, and ensuring large vessels do not sink.

In Indonesia, this is one of the highest-paying jobs, allowing welders to earn up to $15,000 in just one week. The demand for these professionals is so high that the government funds the training of certified diving welders.

Long trips are part of the job for underwater welders.

One aspect of their work involves attaching a white box called a positive anode to iron pillars. The anode is made from a more reactive metal, typically zinc or aluminum. It connects to the columns to protect the main structure. The anode must be replaced every five years.

Water significantly increases the risk of fatal electric shock. A simple mistake of touching the welding gun can result in immediate death. Meanwhile, the welder is only equipped with two pairs of gloves and a standard diving suit. In the United States, divers use more protective measures, yet they still face a mortality rate while working that is approximately 40 times higher than that of the average worker, making it one of the most dangerous jobs.

In Indonesia, this is one of the highest-paying jobs.

Additionally, this occupation involves several other risks such as:

Drowning – Underwater welders face the danger of drowning if their equipment fails or if they lose consciousness. Water pressure at depths can make it very difficult for them to surface safely in emergencies.

Explosions – The combination of flammable welding gases, high pressure, and limited visibility underwater creates a significant risk of explosions. An explosion can result in immediate death or severe injury to the welder.

Electric Shock – The combination of electricity and water is deadly. Faulty welding equipment or poor grounding can lead to fatal electric shock.

Decompression Sickness – Sudden changes in water pressure while ascending and descending can cause bends, which can lead to disability or death if not treated properly.

Hypothermia – Cold water temperatures, even when wearing protective gear, can lead to hypothermia and loss of consciousness over time.