Researchers at the Manufacturing Engineering Center at Cardiff University have successfully developed a method for creating drill holes in steel with a diameter of just 22 microns using electrical discharge machining. These are considered to be the smallest drill holes in the world today.

Researchers at the Manufacturing Engineering Center at Cardiff University have successfully developed a method for creating drill holes in steel with a diameter of just 22 microns using electrical discharge machining. These are considered to be the smallest drill holes in the world today.

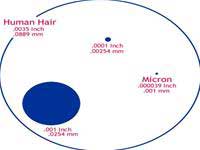

The electrical discharge machining technique utilizes extremely high-intensity electric sparks to create ultra-small holes in suitable materials. According to Space Daily, engineers at Cardiff University used electric sparks with a diameter of only 6 microns to produce drill holes with a diameter of just 22 microns. Frank Marsh, the director of the research center, stated that the holes created by his research team are currently the smallest drill holes in the world.

Frank Marsh indicated that the smallest drill holes previously known are around 150 microns in diameter, all created using laser drilling technology. The laser drilling process cannot be compared to electrical discharge machining, as laser-drilled holes are uneven and cone-shaped, while electrical discharge machining produces consistently cylindrical holes.

The potential applications for this technique of creating ultra-small drill holes are vast, especially in fields such as optics, medicine, and electronics.

HOÀNG KIM ANH (According to Theregister)