Natural wood is a vital resource for construction and furniture making. It is also highly valued for its versatility, renewability, and aesthetic charm.

However, many new potentials of wood are beginning to emerge as scientists devise methods to refine the optical, thermal, mechanical, and ionic properties of wood materials through chemical and physical changes to the inherent porous structure and chemical composition of wood.

To pursue this goal, researchers in recent years have developed innovative strategies to transform wood in relation to new application potentials.

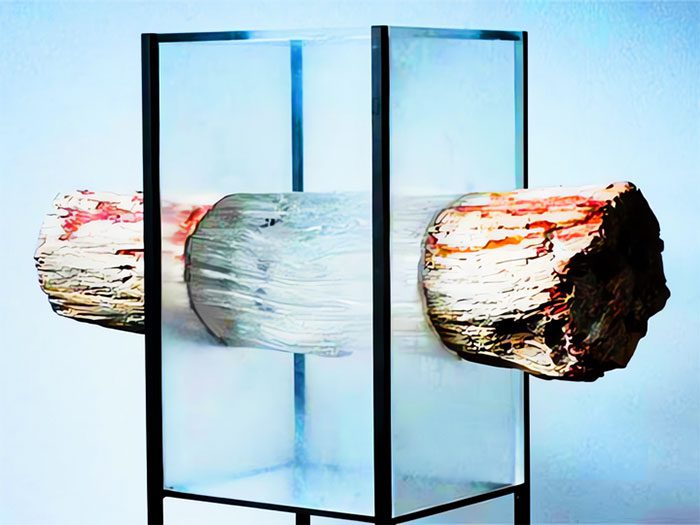

Scientists develop transparent wood for smartphone screens and morphing windows. (Illustrative photo: Shutterstock)

Previously, Siegfried Fink created transparent wood by removing pigments from plant cells in the wood. This technological process was detailed in a specialized journal focusing on wood technology in 1992.

For more than a decade afterward, Siegfried Fink’s 1992 publication was the primary source providing accurate information on transparent wood technology. Another scientist at the Royal Institute of Technology (KTH) in Sweden, Lars Berglund, fortuitously discovered this publication and used it for his own research.

Now, a team of researchers led by materials scientist Liangbing Hu at the University of Maryland in College Park is actively involved in developing transparent wood through direct treatment techniques on natural wood.

According to the research team, wood consists of numerous small vertical tubular cells, akin to a tightly bundled group of straws. These tubular cells function to transport water and nutrients within the tree.

To produce transparent wood, scientists must change or remove a glue-like substance known as lignin. In fact, this substance serves both as an adhesive binding the cell bundles together and as the source of the brownish color of stems and branches.

After bleaching or removing the color from the lignin glue in the wood, opaque white cell walls remain. This is because the cell walls refract light differently than the air in the cell cavities that have had the color-producing glue removed.

To achieve transparency, the air pockets in the wood cells must be filled with a material such as epoxy resin, which bends light and allows the wood to be seen through. The resulting transparent wood allows over 85% of light to pass through. It can capture sunlight without glare, helping to save energy and provide more comfortable indoor lighting.

Transparent wood also possesses strong mechanical integrity, addressing safety concerns typically associated with glass materials. Furthermore, transparent wood surpasses glass in its role as an insulator, helping buildings in expelling heat.

In their work, Liangbing Hu’s research team used polyvinyl alcohol (PVA), a polymer commonly found in adhesives and food packaging, to infuse the treated wood cells. This results in transparent wood with thermal conductivity five times lower than that of glass.

Lars Berglund and his research team at KTH have also discovered a way to replicate the functionality of smart windows made from transparent wood materials. This technology has the capability to switch between transparent and tinted states to control visibility or block sunlight.

Their method involves layering a color-changing electrochromic polymer between layers of transparent wood coated with an electroconductive polymer.

According to some evaluations, as the technology advances, transparent wood materials will become more flexible, more transparent, and more sustainable, with potential applications ranging from ultra-durable smartphone screens to lighting devices.