Bel Albatros, a company based in Brussels, Belgium, is pioneering the transformation of plastic waste into recycled materials for the production of new products.

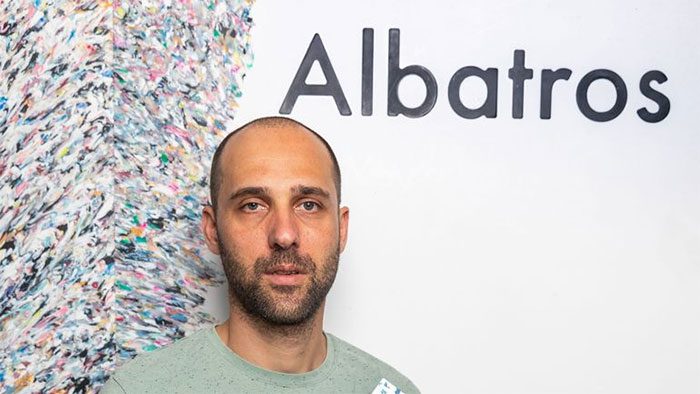

This initiative is led by Guilain Sevriere and Elisabeth Trivière, two founders aiming to promote a circular economy model. By reusing discarded plastic resources, they not only minimize pollution but also cater to the creative needs of young designers.

Chair made from recycled plastic by Bel Albatros. (Photo: N.D).

Guilain Sevriere became interested in recycling while working at a fab lab, a space for digital manufacturing equipped with 3D printers. “During the manufacturing process, plastic waste is unavoidable,” he noted. Unlike wood or metal, plastic is challenging to recycle and generates significant waste. This prompted Guilain to seek solutions for plastic recycling, leading him to discover an online open-source project focused on creating small plastic recycling machines. He then met a plastic manufacturer in Brussels, who helped him access larger technologies and kickstart his career in the plastics industry.

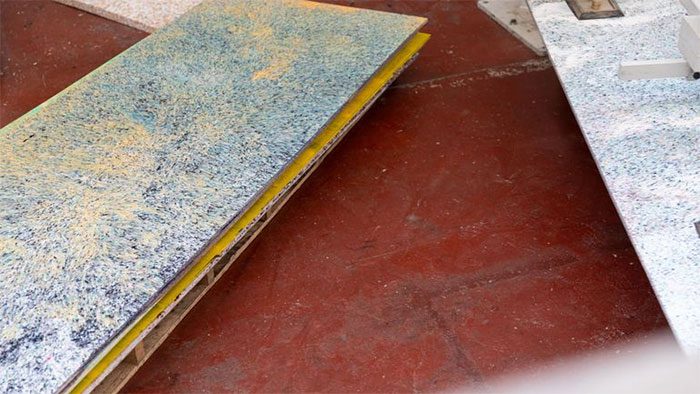

After facing the technical challenges of plastic injection molding, Guilain decided to shift towards producing recycled plastic sheets. When the opportunity arose to purchase a compression molding machine, the company entered a new phase. They began producing large sheets from recycled plastic, which are then used to create furniture, wall panels, and tiles. The manufacturing process includes shredding plastic, compressing it in molds, and heating it before cutting it into finished products.

Guilain Sevriere, founder of Bel Albatros. (Photo: N.D).

Furniture made from recycled plastic. (Photo: N.D).

Bel Albatros is committed to recycling 100% of the plastic waste generated in their production process. (Photo: N.D).

Currently, Bel Albatros recycles about 3 tons of plastic each month. (Photo: N.D).

Bel Albatros sources plastic from various channels, including companies looking to dispose of plastic, recycling organizations, and the plastics industry. Collecting plastic helps these companies reduce waste disposal costs while providing raw materials for Bel Albatros to create environmentally friendly products.

With the technical advantages of plastic, such as water resistance, ease of shaping, and customizable colors, Bel Albatros has attracted the attention of young designers in search of eco-friendly materials. The company collaborates with numerous architects and interior designers to produce innovative furniture and tiles. A notable recent project involved creating 4 kilometers of baseboards for the MIX hotel, a significant project in Brussels.

Bel Albatros is committed to recycling 100% of the plastic waste generated during production, from cutting dust to plastic shavings. This ensures a fully circular production cycle, minimizing waste and reducing environmental impact.

Currently, Bel Albatros recycles about 3 tons of plastic each month and plans to scale up within the next year. The company’s goal is to establish a larger manufacturing facility and install solar panels to enhance sustainability in the production process.

Bel Albatros not only produces recycled plastic products but also contributes to reducing plastic waste, promoting a circular economy, and meeting the growing demand for eco-friendly materials.