If you think this popular seafood is only meant to be eaten and the shells discarded, then you are missing out. A recent study shows the immense potential of what we are currently throwing away.

Transforming Shrimp Shells into Environmental Protection “Weapons”

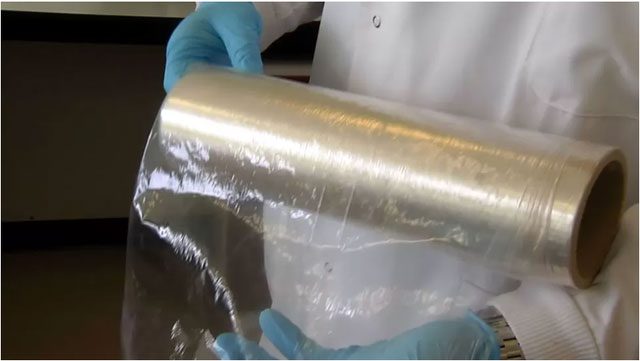

A research team from the University of Nottingham, UK, has recently successfully developed a biodegradable bag made from shrimp shells. The process is quite simple: cleaned shrimp shells undergo chemical treatment and are then dried to become a thin plastic film. This plastic film is then crafted into durable bags that are equivalent to conventional plastic bags but safe for marine animals if ingested.

British scientists have successfully created a biodegradable bag made from shrimp shells. (Photo: The Week)

The substance made from shrimp shells is known as chitosan film, a type of biodegradable polymer that can completely decompose in a short time without causing environmental pollution.

According to the research team, approximately 1 kg of shrimp shells can produce 15 biodegradable bags.

Dr. Nicola Everitt, the team leader, explained: “Using biodegradable polymers extracted from shrimp shells to produce bags instead of plastic bags will help reduce carbon emissions, as well as decrease the amount of food and packaging waste accumulating on streets or in illegal landfills.”

Using biodegradable bags made from shrimp shells can help protect the environment. (Photo: The Week)

“In addition to turning shrimp shell waste into useful products, the project also aims to reduce the number of plastic bags used and accumulating in the environment, which can have adverse effects on the ecosystem and local residents,” Everitt added.

This project is currently being implemented in Egypt, where waste management is one of the country’s biggest challenges. The project has also been identified as a national priority. The research team hopes that within the next 10-15 years, biodegradable plastic products made from shrimp shells can be exported to international markets.

Biodegradable bags made from chitosan film derived from shrimp can replace petroleum-based nylon bags. (Photo: The Week)

Moreover, biodegradable bags made from chitosan film derived from shrimp can fundamentally replace petroleum-based nylon bags and become a powerful tool for environmental protection.

So, what outstanding advantages does chitosan film have that scientists believe it can save the future of our planet?

Chitosan Film – The Material of the Future

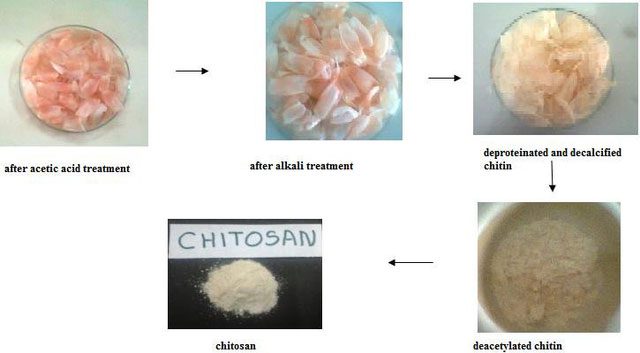

Chitosan film is produced through the N-deacetylation reaction of chitin in the shells of crustaceans and insects in a sodium hydroxide (NaOH) alkaline solution (also known as the deacetylation process of chitin). The degree of deacetylation is used to distinguish between chitin and chitosan. When the deacetylation level of chitin is greater than or equal to 50% (depending on the source of the polymer), it becomes soluble in acidic environments and is referred to as chitosan.

Chitosan film has many superior advantages compared to PET plastic materials. (Photo: The Week)

Chitosan film and its derivatives exhibit antibacterial properties, inhibiting the activity of certain bacteria such as E. coli, killing some harmful fungi, and effectively preserving hard-skinned fruits and vegetables.

According to Dr. Everitt, when compared to other properties of PET plastic—a type of industrial plastic commonly used to produce packaging, plastic bags, bottles, and food containers—this new material has better gas impermeability, which means food can be preserved longer. “The material we have developed shows that it has approximately 67% better oxygen barrier properties compared to PET plastic, thus theoretically, this material can keep food fresher for a longer time.”

Theoretically, bags made from chitosan film can keep food fresher for a longer time. (Photo: The Week)

From these advantages, it is clear that products made from shrimp shells, such as bags and containers, represent a “green” solution to replace traditional plastic products.

Shrimp – The “Export King” of Vietnam’s Seafood Industry

Vietnam is one of the countries with a rich seafood resource and is also a leading export item; you may not know that shrimp is the “trump card,” accounting for the largest share.

Shrimp exports in Vietnam account for a large share due to the country’s rich seafood resources. (Photo: Vietnamplus)

According to the Government Electronic Newspaper, a report from the General Department of Fisheries shows that in 2022, the shrimp industry experienced significant growth in both production and export value. The estimated export turnover reached 4.1 – 4.2 billion USD, an increase of over 10% compared to 2021. This is the highest figure ever recorded, surpassing previous years: 3.4 billion USD in 2019, 3.7 billion USD in 2020, and 3.9 billion USD in 2021. The production plan for shrimp in 2023 aims for export turnover to exceed 4.3 billion USD.

Vietnamplus cites a report on the shrimp industry from 2016-2021 and forecasts for 2025 by the Vietnam Association of Seafood Exporters and Producers (VASEP), analyzing that the area for shrimp farming across the country currently exceeds 740,000 hectares, with production reaching over 900,000 tons per year.

Most of the shrimp exported from Vietnam is processed as peeled shrimp, with heads removed or as shell-off shrimp, resulting in byproducts. (Photo: Vietnamplus)

However, most of the shrimp exported from Vietnam is processed as peeled shrimp, with heads removed or as shell-off shrimp, leading to byproducts from the shrimp processing industry primarily consisting of heads, shells, meat scraps, and spoiled shrimp. According to the Ministry of Industry and Trade, the estimated amount of shrimp waste in Vietnam is around 325,000 tons per year. With the growth of the shrimp processing industry, the amount of shrimp byproducts could exceed 450,000 tons by 2025, corresponding to over 1,000 tons of byproducts being discarded from the production line daily. This enormous amount of waste, if released into the environment, can directly affect pollution levels.

The vast quantity of shrimp byproducts can directly impact environmental pollution if released into the environment. (Photo: The Week)

Mr. Phan Thanh Loc, General Director of VietNam Food, shared that if the shrimp byproducts were fully utilized, they could contribute at least 10% to the value of the shrimp industry. However, currently, businesses are only able to use a portion of these byproducts, and this segment lacks the technology for production, leading to insufficient investment and attention. Furthermore, purchasing shrimp heads and shells solely for animal feed yields limited economic benefits, as one kilogram of shrimp heads sold raw to the animal feed industry only brings in a few thousand Vietnamese dong, not to mention fluctuating prices. However, when using shrimp shells as raw materials for producing biodegradable plastic bags, synthetic plastics, and many other areas, the selling price can reach 400 – 500 USD/kg.

When using shrimp shells as raw materials for producing biodegradable plastic bags, synthetic plastics, and many other fields, the selling price can reach 400 – 500 USD/kg. (Photo: The Week)

Thus, given the daily amount of shrimp byproducts discarded, if Vietnam utilizes shrimp shells to create eco-friendly plastic products, it could simultaneously address pollution issues in agricultural production while generating substantial profit for the shrimp industry.