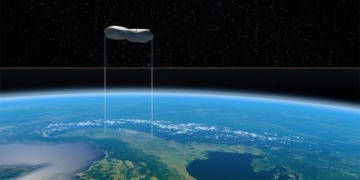

Massive bridge segments weighing hundreds of tons are positioned and connected to the bridge piers with remarkable precision and efficiency by a specialized machine.

It is hard to deny that China is one of the countries with a highly developed construction industry. In addition to utilizing conventional technologies, the country boasts gigantic machines specifically designed to rapidly connect bridge segments.

The SLJ900/32 is involved in the construction of long multi-span bridges at remarkable speed.

This is the SLJ900/32 bridge girder launching machine, which weighs up to 580 tons and is manufactured and assembled by Beijing Wowjoint Machinery Company.

The SLJ900/32, also nicknamed the “Iron Monster,” represents a significant advancement in bridge construction. It specializes in lifting, transporting, and placing precast bridge segments at a speed of 5 km/h, significantly reducing on-site assembly time. The machine measures 91.8 meters long, 7.4 meters wide, and 9 meters high, capable of lifting loads up to 900 tons.

Together with many other machines, the Iron Monster is an innovation that helps China achieve its goal of connecting three continents through a network of sea and land routes. Designed by the Shijiazhuang Railway Institute and produced by the Beijing Wowjoint Machinery Company, the SLJ900/32 is involved in the construction of long multi-span bridges with impressive speed.

One of the many notable projects where the SLJ900/32 was deployed is the Jinsha River Railway Bridge in Yuxi. Before the bridge was built, the travel time between Sichuan Province and Guizhou was 12 hours. However, this travel time has now been reduced to just 3 hours. Another example is the high-speed rail line connecting Inner Mongolia to the rest of the country, which is part of China’s plan to build a 30,000 km railway network.

The bridge-building machine moves on 64 rotating wheels divided into 4 clusters. Construction begins when the machine transports girders from the edge of the bridge to the installation position and connects them to pre-placed piers. Then, using a pneumatic structure, the machine is anchored to the first pier to gradually move to the second pier. The SLJ900/32 will place the next bridge girder with similar steps. Although it requires fewer workers compared to building bridges with cranes, the Iron Monster still needs a team of engineers to oversee the entire process as well as to maintain and clean its components.

The machine operates very efficiently, especially in large construction projects, due to its reduced reliance on human labor, cutting down on scaffolding costs, and increasing progress. Furthermore, the 580-ton machine also adds additional load capacity for the bridges. With a lifespan of 4 years, the machine can install 700 to 1,000 bridge spans throughout its operational period.