Dr. Nguyen Chung and his team in Australia are researching the development of ultra-small sensors capable of detecting ammonia in breath, providing warnings about potential health issues.

Dr. Nguyen Chung, 35 years old, is a Vietnamese researcher at RMIT University (Australia) and the lead author, and he is the only Vietnamese member collaborating with scientists from RMIT University, the University of Melbourne, and the Centre of Excellence for Photonic Nano Systems (TMOS) under the Australian Research Council (ARC) on this research.

The sensor consists of a transparent and ultra-thin tin oxide film, which can easily detect ammonia at levels significantly lower than similar technologies. The device functions like an electronic “nose,” capable of detecting even the smallest amounts of ammonia. The sensor can also distinguish between ammonia and other gases with higher accuracy than other technologies.

In an interview with the press, Dr. Nguyen Chung revealed that the idea for the research emerged in early 2022. The project took nearly a year to complete most of the measurements by May 2023. The findings were published in the leading materials science journal Advanced Functional Materials in November 2023.

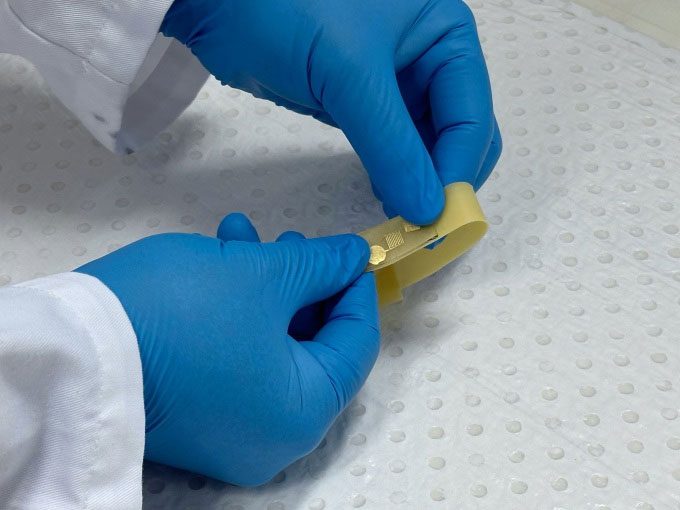

Research team attaching ultra-thin tin oxide to the substrate. (Photo: Seamus Daniel/RMIT).

Dr. Nitu Syed, the research team leader, explained that the presence of ammonia in the air alters the resistance of the tin oxide film in the sensor, meaning the higher the concentration of ammonia, the greater the change in resistance of the device. The research team conducted experiments with the sensor in a specially designed device to test its ability to detect ammonia at various concentrations (5 – 500 ppm) and under different conditions, including temperature. They also evaluated the accuracy of the device in distinguishing ammonia from other gases, such as CO2 and methane. The results demonstrated that this sensor can detect ammonia at very low concentrations, making it suitable for detecting ammonia in breath to warn of potential health disorders.

To manufacture the sensor, the team utilized a low-cost technique that can be easily scaled up to attach ultra-thin tin oxide to the substrate. This technique is feasible even on flexible materials, which often complicate other fabrication methods. The team obtained the tin oxide film from the surface of molten tin at a temperature of 280 degrees Celsius. This film is 50,000 times thinner than paper. “Our method requires only a single synthesis step without any toxic solvents, vacuum environments, or bulky and expensive equipment,” described Dr. Ylias Sabri from the School of Engineering at RMIT University (Australia).

Key researchers Dr. Nitu Syed, Dr. Ylias Sabri, and Dr. Nguyen Chung (from left to right) in the laboratory at RMIT University. (Photo: Seamus Daniel/RMIT)

Dr. Nguyen Chung noted that this miniaturized sensor provides a safer and more compact solution for detecting toxic gases compared to existing techniques. Current ammonia detection methods yield accurate measurements but require expensive laboratory equipment operated by skilled technicians, along with multiple samples and complex preparations. This process is often time-consuming and not portable due to the bulky equipment. Additionally, producing ammonia detection sensors typically necessitates costly and complex processes to prepare sensitive material layers for sensor fabrication.

The new sensor from the team can immediately distinguish between safe and dangerous levels of ammonia in the environment. “This tin oxide attachment technique can be scaled up, thus presenting the opportunity for mass production at a more reasonable cost,” he stated.

He mentioned that the team faced challenges when characterizing the material properties due to the ultra-thin nature of the material (the tin oxide used by the team is only 2 nanometers thick). Establishing a reliable gas measurement system was also a challenge. However, collaboration with numerous researchers and experts from RMIT and the University of Melbourne helped the team overcome these challenges.

The team hopes to collaborate with industry partners to continue developing and manufacturing the next version of this sensor to optimize its functionality. Their method is compatible with existing manufacturing processes in the silicon industry, making it suitable for mass production.

It is estimated that approximately 235 million tons of ammonia are produced globally each year to meet the demands of various industries. Ammonia is promoted as one of the effective methods for hydrogen storage in the production of green fuels, and ammonia production is expected to increase in the coming years. However, exposure to high concentrations of ammonia can lead to chronic lung disease and irreversible organ damage. Ammonia gas leaks during transportation and plant operations pose significant risks and can be life-threatening. Therefore, the ability to detect ammonia effectively and reliably is essential for ensuring safety. This gas is also found in human breath and can serve as an important “biomarker” for diagnosing various diseases, such as kidney and liver disorders. Dr. Nguyen Chung obtained his Master’s degree in Chemical Engineering from Ho Chi Minh City University of Technology in 2014. He is currently a researcher at the School of Engineering at RMIT University, where his primary research focuses on liquid metal chemistry and the synthesis of 2D materials for use in electronic applications and sensors. |