Mecanum wheels have been a widely discussed topic for the past 50 years. This unique tire design was once hailed for offering a revolutionary driving experience, yet surprisingly, its application on commercial vehicles has been delayed.

Challenges of Stability and Safety

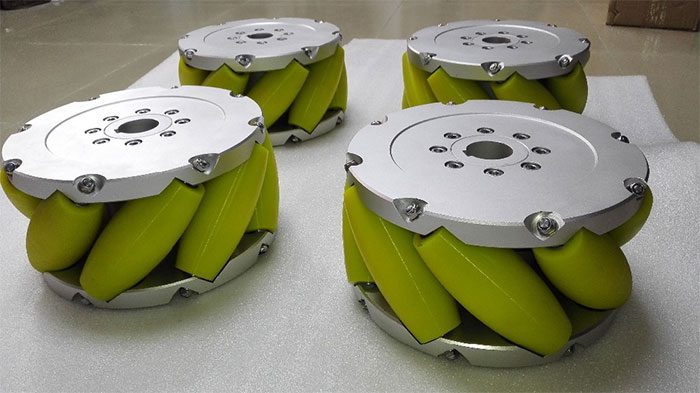

As technology continues to evolve, the automotive industry relentlessly pursues innovation and improvement. However, the reason why Mecanum wheel technology is not utilized in commercial vehicles remains a hotly debated topic. Mecanum wheel technology is a wheel design that allows for omnidirectional movement. It consists of four special wheels that can rotate independently and have independent drive forces.

This design enables vehicles to achieve much greater agility and flexibility compared to traditional commercial cars, while also offering exceptionally high maneuverability and steering capability. In fact, Mecanum wheel technology is currently used extensively in various fields such as robotics, logistics, and warehousing, among others.

Although Mecanum wheel technology has achieved significant success in the fields of robotics and logistics, its application in the commercial automotive sector remains limited due to challenges related to stability and safety. (Photo: Zhihu).

For commercial vehicles, stability is an extremely critical factor. The Mecanum wheel technology can affect the stability of commercial vehicles to some extent and pose safety risks for drivers and passengers. Due to the design of the Mecanum wheel, the vehicle’s footprint is relatively small, which can make it easier for the vehicle to tip over or lose control when driving at high speeds. This is unacceptable for a commercial vehicle.

In addition to the stability issue, Mecanum wheel technology also presents challenges to the safety of passenger vehicles. In emergency braking or evasive situations, traditional wheel designs enhance vehicle stability and reduce the likelihood of lateral skidding. However, the unique design of Mecanum wheels can lead to instability during emergency maneuvers, increasing the risk of accidents.

Mecanum wheel technology is also more complex and expensive compared to traditional wheel designs. The Mecanum wheel design requires each wheel to be driven independently, meaning there are more mechanical and electrical components involved. This results in higher production costs for passenger vehicles and increases the challenges of repair and maintenance. Additionally, not all road conditions are suitable for Mecanum wheel technology, which further limits its application in the commercial vehicle sector.

Commercial vehicle manufacturers need to ensure stability and safety in all circumstances, which has become one of the main reasons why Mecanum wheel technology is not adopted in commercial vehicles. (Photo: Zhihu).

Surrounded by Challenges of Cost and Production

Mecanum wheel technology is a control technology commonly used for advanced mobile robots and autonomous positioning systems. It allows robots to move smoothly and efficiently in all directions. However, despite its widespread use in robotics, Mecanum wheel technology has not been widely adopted in the commercial automotive industry. This is primarily due to challenges related to cost and production.

The production and installation of Mecanum wheels require more materials and processes, leading to increased production costs for vehicles. These special wheels also require a more complex control system to ensure normal operation, and for electric vehicles, larger batteries or power sources are needed to provide the high power necessary to drive Mecanum wheels. These additional costs can increase vehicle prices, which may not be attractive to consumers.

Compared to conventional tires, designing and manufacturing Mecanum wheels is more complex. It consists of several smaller wheels, each of which needs to be driven and controlled independently. This means that manufacturers require more complex production processes and equipment. The unique structural design of Mecanum wheels also demands higher precision and accuracy to ensure normal operation, representing a technical challenge for manufacturers. (Photo: Zhihu).

Mecanum wheel technology also has some performance limitations, which is one of the reasons it has not been widely adopted in the commercial automotive industry. Although Mecanum wheels can achieve strong agility and flexible steering, they do not perform well in terms of suspension and traction. (Photo: Zhihu).

Commercial vehicles are mass consumer products, and market demand plays a crucial role in the choice of technology applications. Although Mecanum wheel technology can offer excellent handling performance, it does not provide significant benefits to consumers when driving on regular roads, and it may even increase vehicle costs. (Photo: Zhihu).

Mecanum wheel technology has not been widely applied to passenger vehicles primarily due to technological application limitations arising from market demand and convenience issues. Consumers pay more attention to factors such as fuel efficiency, safety, and convenience, and Mecanum wheel technology does not offer consumers significant clear benefits in these areas, and may even cause comfort issues.