Why Do 9 Decommissioned Russian Missiles Contain Nearly 42kg of Silver and 1.8kg of Gold?

In 2018, the news agency Sputnik reported that the Russian Federal Space Agency (Roscosmos) announced a tender project for the dismantling of 9 RT-2PM Topol missiles that had been decommissioned.

The dismantling contract was worth 9.7 million rubles (equivalent to 170,817 USD at that time) and required the missile dismantling to be completed before November 2018.

Roscosmos indicated that the winning contractor could extract nearly 42kg of silver and 1.8kg of gold from these 9 missiles. Each missile contained approximately 198g of gold, 4.6kg of silver, and 5g of platinum distributed across various parts.

However, the winning contractor would have to pay the proceeds from the sale of the gold and silver to the Russian government.

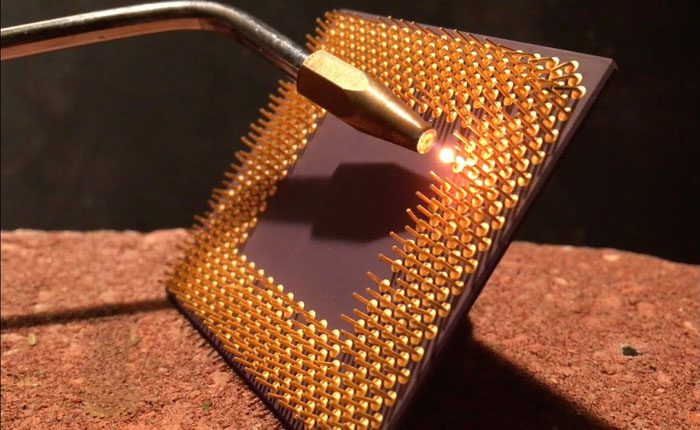

The gold plating method is used in electronics and defense technology.

Regarding the presence of gold in missile components, Science Focus explained that many years ago, manufacturing companies in Russia and worldwide began to use gold plating and other metal finishing services to enhance the expected lifespan of their products, helping to reduce wear and improve conductivity as well as connectivity.

The commonly used method is electroplating, which involves using electric current to apply a layer of metal onto the surface of an object. The metal being deposited (such as gold) is connected to the positive electrode of the circuit (anode). The object to be plated (substrate or base material) is connected to the negative electrode. A special solution is designed to facilitate the electrolysis process here.

Common applications of electroplating include reducing friction, providing protection against damage and surface wear, improving electrical conductivity for electronic devices, and even enhancing the surface’s adhesion before painting.

Thanks to this method, many different missile components can be protected, such as communication system parts, guidance system components, optical devices, and aerospace electronics.

As electronic devices and resistors have become more sophisticated, gold has increasingly been chosen for plating, especially for electrical contact points. In the United States, it is estimated that over 320 tons of gold plating is used in the electronics industry each year, primarily in consumer electronics such as computers, mobile phones, and tablets. Gold is resistant to corrosion at both high and low temperatures.

Gold also has many applications in aerospace.

Gold has many applications in aerospace. It is one of the best-known reflective materials that scientists are aware of today. By gold-plating defense parts and components, manufacturers and scientists can ensure “low resistance” and “stable contact” – two very valuable conditions when it comes to defense electronic devices.

Furthermore, as mentioned above, corrosion resistance is another outstanding benefit, especially for systems with an expected lifespan of several decades.

One emerging application of gold is as a catalyst. Typically, oxide layers form on many other metals when they come into contact with the ambient air, reducing their conductivity. They can also corrode and rust due to chemical reactions occurring during oxidation.

Since gold does not oxidize, it can ensure that the plated surface remains very smooth and reliable, maintaining good and stable connections.

Gold is also used for electrical connections, especially those connections where the oxidation process can significantly reduce the conductivity of the conductors.

Finally, gold helps dissipate heat, as gold-plated contacts can be used at much higher temperatures than contacts plated with other metals, up to 125 degrees Celsius.