Batteries are typically arranged in opposing directions and next to each other to allow for a smooth flow of electricity without needing additional hardware. When batteries are arranged in a series, the positive (+) and negative (-) terminals must be connected alternately, making this design more efficient and easier to implement.

Think back to your childhood and the joy you felt when unboxing a brand new toy – a remote-controlled car, action figures that could move, light up, and play music, or even a toy phone. After tearing off the wrapping paper, the most important thing you needed to find was the batteries so you could power it up and start having fun. However, one thing you have surely noticed and seen hundreds of times since then is the visual instructions indicating that the batteries must be installed in opposing directions.

Of course, placing batteries in a row in opposing directions is not difficult, but it raises the question – why are batteries designed this way?

Batteries are arranged in opposing directions so that the positive terminal of one battery is next to the negative terminal of another.

Before we can understand the nuances of battery integration and product design, we should take a quick look at what a battery is. A battery, quite simply, is a collection of electrochemical cells with external connections that allow it to power electronic devices. From small batteries used in hearing aids and smartphones to enormous batteries for electric vehicles, there are several fundamental components of batteries that remain unchanged.

When using a battery, the positive terminal connects to the negative terminal, and the negative terminal connects to the positive terminal. Electrons flow from the external circuit into the positive terminal and move toward the negative terminal. A redox reaction occurs that converts high-energy reactants into lower-energy products; the remaining energy is then available for the device or product to use as electrical energy, powering the device.

Rechargeable lithium-ion battery.

Essentially, the chemical energy in the battery is converted into electrical energy in the form of direct current (DC). The chemicals contained in the battery are often acidic and are referred to as electrolytes. The battery itself can be made from nickel, lithium, cadmium, lead, mercury, and alkaline materials, each having its own advantages and disadvantages. Today, lithium-ion batteries have become extremely popular due to their high energy density, allowing them to provide a lot of energy from a small source and have high rechargeability.

Previously, traditional batteries had many cells connected together, but modern batteries can now contain multiple cells within themselves. However, when multiple batteries are used together, they are often arranged in series, allowing them to double both voltage and amp-hour (the amount of energy stored in the battery that allows one amp of current to flow for one hour). An alternative option for batteries is to be arranged in parallel (increasing amp-hour while keeping voltage constant), but this option may not be suitable for devices that require a higher voltage level.

If two batteries are arranged in the same direction, meaning they are in parallel, you will only have the voltage equal to one battery, whereas, when connecting two batteries in opposing directions, that is in series, you will have the total voltage equal to the sum of the two batteries’ voltages.

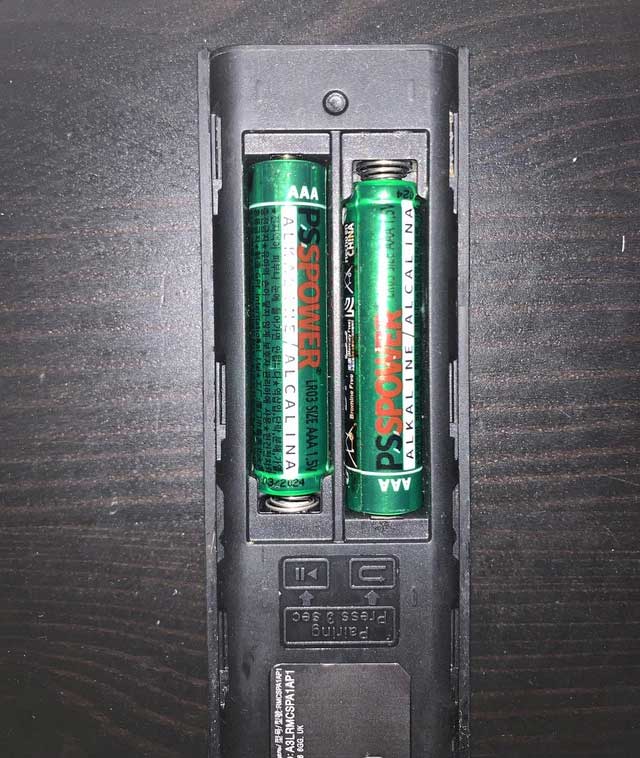

When multiple batteries are arranged in series, the positive and negative terminals of adjacent terminals must be connected; this is how the electricity can flow through, completing the circuit and powering the device. With that in mind, arranging batteries in an alternating pattern – a battery with the positive (+) terminal facing up, followed by a battery with the negative (-) terminal facing up is efficient.

If the batteries are arranged with the same terminals all facing in one direction, a wire must be included in the design to connect the positive and negative terminals of neighboring batteries, resulting in more material waste. However, with batteries alternating their terminal orientation, a small metal strip at both ends of the battery can establish this essential connection – between the positive (+) and negative (-) terminals.

Depending on the product design, batteries may need to be arranged side by side or in a row. In the latter arrangement, often seen in flashlights, the positive and negative terminals are compressed and held close together, allowing for smooth current flow. In other products, such as handheld gaming consoles, tightly compressing multiple batteries side by side in alternating directions is the most efficient design in terms of completing the circuit.

When designing a product, every millimeter must be considered; even the addition of a secondary wire is seen as wasteful and can add to the final production costs. Manufacturers and designers are constantly seeking cost-effective solutions that do not compromise functionality.

Arranging batteries in this upright manner and linking the positive and negative terminals with a metal strip, rather than with wires, will improve the performance and efficiency of the design. The orientation of the batteries (in a row or adjacent) depends on the overall shape and other physical components of the product.