When we think of horses, we immediately associate them with their remarkable speed, which brings to mind the resonating sounds of “clop… clop…” made by their hooves. But why do horses make such loud sounds when they run? It turns out that humans have fitted horses with iron shoes—iron hooves. But why do we need to shoe horses? This practice dates back to the horse’s hoof structure.

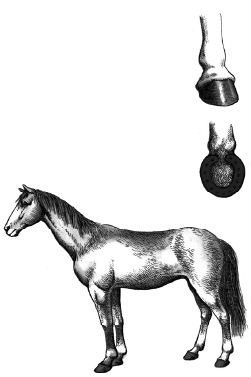

Today’s horses have only one toe at the tip of each limb, akin to the middle finger in humans, while the other toes have degenerated over time. This single toe is covered with a hard, protective hoof. The horse’s hoof is essentially a hardened piece of skin. The hardened layer at the front and sides is thick and strong, known as the hoof wall.

Applying iron shoes to protect the horse’s hooves from wear.

The hardened layer at the front of the horse’s foot is referred to as the sole. The hoof wall and sole, along with the internal bone structure, create a solid unit that prevents the horse from becoming unstable while running. The underside of the hoof, which includes the heel area, has a softer, more elastic layer that absorbs the impact from the ground.

The horse’s hoof does not entirely touch the ground; only the edges of the hoof and the hoof wall make contact. This small surface area allows horses to run quickly on hard roads and arid fields.

With a great load-bearing capacity and superior speed, horses have long been used as a means of transportation and cargo by humans. In the early days of horse domestication, it became apparent that with high movement intensity, natural hooves would become overloaded and wear down, affecting their running capabilities and speed.

To address this issue, iron shoes were invented to serve as a protective cushion for the horse’s natural hooves.

The horse’s hoof is a short, hardened piece of skin that supports the animal’s weight. Continuous contact with hard ground leads to wear and deformities on the hoof, which negatively impacts speed and the ability to carry loads. Eventually, humans devised a solution: to shoe horses with iron to prevent hoof wear.

However, shoeing is not done arbitrarily. Before applying the iron shoe, the hoof must be trimmed and shaped to ensure a flat bottom edge and hoof wall. The most suitable iron shoe is selected to snugly fit the horse’s hoof. Finally, nails are driven into the holes of the iron shoe. The nails are positioned at the area where a circular band lies between the sole and the hoof wall. When nailing, the nails should be angled outward, piercing the hoof wall without harming the horse’s sensitive structures. The protruding tips of the nails must be cut off, and the remaining portion bent to secure the iron shoe firmly to the hoof.

Even after shoeing, the process is not complete. The horse’s hoof, much like human fingernails, continues to grow. Without regular checks and maintenance, the hoof can become deformed, and the iron shoe may not function effectively.

Therefore, the horse’s shoes must be adjusted several times a year. If the iron shoes become excessively worn, they must be replaced promptly. Only by doing so can we properly protect the horse’s hooves and fully harness their ability to run long distances.

Why do horses need shoes while livestock do not?

Livestock, although also domesticated and used for work in fields like horses, do not require shoeing. The main reason lies in the physiological structure and living conditions of the two species.

Horses are ungulate animals, with one well-developed toe, whereas livestock are even-toed ungulates, possessing two well-developed toes. The toes of livestock help distribute weight more evenly when moving on soft ground, making them well-suited for pasture and agricultural work. This characteristic reduces hoof wear and lessens the need for additional protection like that used for horses.

Additionally, livestock typically live and work on softer ground, which does not exert significant pressure on their hooves as the hard surfaces do for horses. Consequently, the risk of hoof wear or injury in livestock is much lower than in horses.

The horse’s hoof has a unique structure that is thin and prone to wear when in direct contact with hard surfaces.

Horses are often used for riding, pulling carts, and performing tasks that require quick and continuous movement. This necessitates better protection for their hooves. In contrast, livestock are primarily used in agriculture, such as plowing fields and pulling carts slowly. Furthermore, livestock thrive in milder environments where the ground is soft and less damaging to their hooves.

Another distinguishing factor is that horses are heat-tolerant animals, capable of adapting to arid environments, while livestock thrive in cooler, more humid conditions. This trait allows horses to work efficiently on hard surfaces, whereas livestock perform better in softer soil conditions.

Horses are used for riding, pulling carts, and participating in sports, which require them to move across various terrains, from hard roads to soft dirt paths. Shoe application helps protect their hooves, reduce friction, increase traction, and enable more agile movement. Livestock, on the other hand, are often confined or move within limited ranges, typically on soft surfaces like grass. Thus, their hooves experience less wear and do not require shoeing.

The distinction between shoeing horses and not shoeing livestock results from differences in physiological structure, living environments, and the functional roles of the two species. Horses, with their specific roles, need additional hoof protection to ensure effective work performance and maintain health. Conversely, livestock, with hoof structures suited to soft soil and less demanding work, can function well without the need for shoes. This difference reflects not only the biological characteristics of each species but also the result of thousands of years of domestication and usage in agriculture and human life.

- The nearly 1m long hooves of two horses that went 15 years without trimming

- Photo of the “wall” of the universe stretching 50 trillion km

- 5 amazing things that can be made from plastic waste produced by humans daily

- NASA offers a reward of 5 million USD for anyone who can “advise” effective management of power on the Moon