The Massachusetts Institute of Technology has designed a surface with tiny dimples to effectively trap bubbles generated when heating water, leading to more efficient boiling.

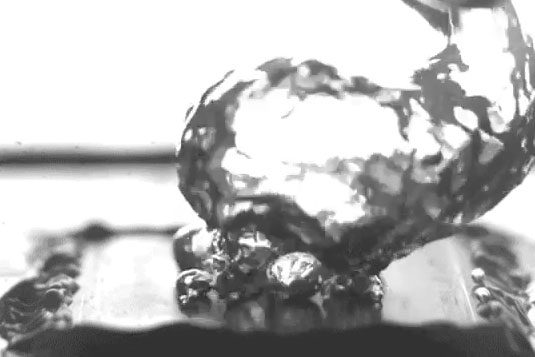

A slow-motion video capturing 100 times the speed of a boiling water experiment on a specially treated surface shows bubbles forming at distinct locations rather than spreading out into a film. (Video: MIT)

Quick and efficient boiling of water can be beneficial for various industrial processes in power generation plants, chemical production systems, and cooling systems for electronic devices due to energy savings. Scientists at the Massachusetts Institute of Technology (MIT) have developed a new method to achieve this, as announced by the institute on July 12.

Specifically, the team of experts found a way to simultaneously improve two key parameters that facilitate the boiling process: heat transfer coefficient (HTC) and critical heat flux (CHF). This is a significant advancement because there is typically a trade-off between these two parameters—improving one can worsen the other.

“Both parameters are important, but improving them simultaneously is challenging due to the trade-off. If there are many bubbles on the boiling surface (the surface of the material heating the water), the boiling process is very efficient. However, if there are too many bubbles, they can coalesce, forming a vapor film above the boiling surface,” said Dr. Youngsup Song, a co-author of the study.

This vapor film hinders heat transfer from the hot surface to the water. “If there is vapor between the surface and the water, it will impede effective heat transfer and reduce the CHF value,” the research team noted.

In their new study, the scientists added a series of tiny dimples to the surface of the material, controlling how bubbles form on that surface. This effectively pins the bubbles to the locations of the dimples, preventing them from spreading out and forming a thermal barrier.

The team then adjusted the positioning of the dimples to optimize this process. “The micro-dimples determine where the bubbles appear. By spacing the dimples 2 mm apart, we can separate the bubbles and reduce the likelihood of bubble coalescence,” Song explained.

The new method shows great promise, but according to Professor Evelyn Wang of MIT, a co-author of the study, it has only been tested in a small laboratory setting, and scaling it up for practical application in modern devices will be more challenging.

Currently, the research team is focused on finding additional measures to create surface structures that can be used in real-world applications. “Demonstrating that we can control the surface to enhance efficiency is the first step. The next step is to think about methods that are easier to scale up,” Wang concluded.