For the first time in the world, American researchers create bio-cement from microalgae to reduce carbon emissions.

A team of researchers from the University of Colorado Boulder, the University of North Carolina Wilmington, and the U.S. National Renewable Energy Laboratory has developed a unique carbon-neutral method using cement that can be produced from biological limestone. This new material promises to significantly mitigate environmental pollution caused by construction activities worldwide.

According to a report from the U.S. Environmental Protection Agency (EPA), cement ranks third among the ten largest sources of industrial pollution. Approximately 2 billion tons of CO2 are emitted into the environment each year due to the production and use of cement. It is hard to imagine construction activities without concrete and cement, especially Portland cement.

Highlighting the significance of concrete, the research team leader Wil Srubar, a professor at the University of Colorado Boulder, noted that the commercial production process of Portland cement involves burning large amounts of limestone, resulting in CO2 emissions, pollutants, and toxic gases that severely impact the air quality of surrounding areas.

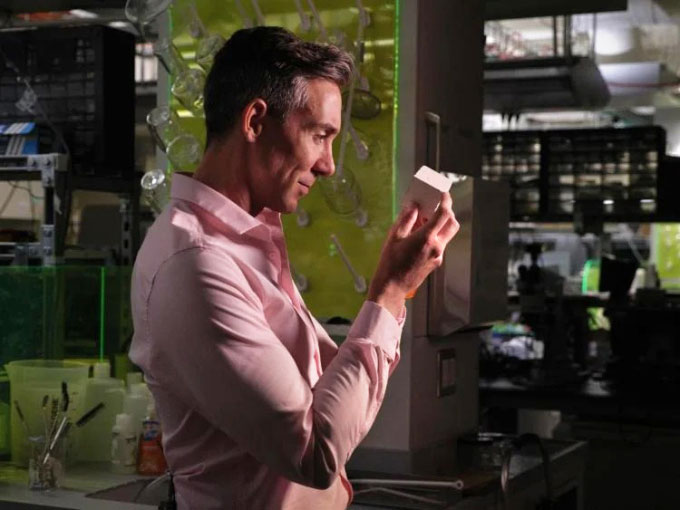

Wil Srubar holding a sample block of concrete developed from microalgae. (Photo: Glenn Asakawa)

The solution to this problem came to Srubar in 2017 during a trip to Thailand, where he observed naturally occurring calcium carbonate (CaCO3) structures around coral reefs. Limestone is also formed from calcium carbonate. Looking at the CaCO3 deposits, Srubar thought that limestone could also be cultivated naturally rather than mined. He asked himself, “If nature can cultivate limestone, why can’t we?”

Upon returning to the U.S., Srubar and his colleagues decided to cultivate a group of microalgae known as Coccolithophore. Members of this algal group can produce biological limestone by forming calcium carbonate deposits during photosynthesis. The research team found that, unlike natural limestone which takes millions of years to form underground, the biological version of Coccolithophore can be produced in real-time.

Furthermore, Coccolithophore produces calcium carbonate faster than the coral reefs that Professor Srubar observed in Thailand. The raw materials needed to form biological limestone in seawater include only dissolved carbon dioxide and sunlight. Additionally, since microalgae can thrive in both saltwater and freshwater, they can be used to produce limestone almost anywhere.

Remarkably, producing cement from biological limestone not only neutralizes carbon but also removes carbon as microalgae absorb CO2 from the environment and store it as calcium carbonate. Consequently, the concrete formed from this cement could herald a new era of sustainable construction worldwide.

With this groundbreaking research, Srubar has been awarded the CAREER award from the National Science Foundation, and recently, his team received a $3.2 million grant from the U.S. Department of Energy. They have also collaborated with several private companies to scale up research and production activities related to biological limestone.