Although they may appear similar on the surface, the use of small stones under railway tracks serves various reasons and purposes.

1. The Role of Ballast Under Railway Tracks

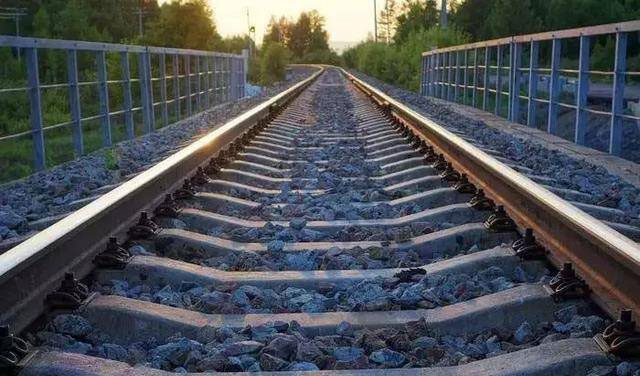

Travelers who enjoy train journeys often notice the abundance of stones surrounding the tracks as they sit by the window. However, many do not understand the essential role that these stones play for the railway.

In fact, the stones next to the tracks are not ordinary rocks. Technically, this type of stone is referred to as ballast. Ballast is not just random small stones; they must meet specific durability standards and serve particular functions.

In fact, the stones next to the tracks are not ordinary rocks.

When laying ballast for railway tracks, materials such as granite, basalt, and limestone are typically used. By distributing these relatively hard stones, the load on the ties and tracks is reduced, which helps to distribute the pressure exerted by the moving train, preventing wear on the tracks.

Of course, advantages come with disadvantages. This type of stone track can present challenges for train operation, particularly on certain curved sections. As the train passes through, the inertia can cause the ballast to scatter.

In traditional rail systems, the layer of ballast plays a crucial role. When a train runs over the tracks, the track framework generates significant vibrations. These stones help absorb and balance those vibrations, preventing track settlement and ensuring the train’s safety during travel. This is why traditional tracks are always laid with a thick layer of ballast, known as ballasted track.

The layer of ballast under the tracks plays a crucial role.

Additionally, the maintenance and replacement of ballast around the tracks can be quite challenging. Prolonged train operation leads to a certain degree of wear on the ballast layer. Coupled with harsh winter weather (especially in snowy regions), the ballast layer can become unstable. Therefore, to ensure safe train travel, regular replacement and maintenance are necessary.

Ballasted tracks have a simple structure, low cost, and are easy to replace and repair. These small stones ensure stability for traditional trains, minimizing the risk of derailment and keeping trains safely moving along the routes.

These small stones ensure stability for traditional trains.

2. High-Speed Rail: Modern Technology and Differences

In contrast to traditional railways, high-speed rail does not use a ballast layer under the tracks. Instead, they are constructed from composite materials such as concrete and asphalt. The reason is that the speed of high-speed trains is very high; if ballast were used, the stones could be ejected with great force, damaging surrounding objects and potentially endangering passengers.

The non-ballasted tracks of high-speed rail are designed to withstand high pressure and vibrations at high speeds. Modern materials like concrete and asphalt provide greater stability for the tracks, reducing the risk of damage and derailment. They also help distribute the weight of the train, preventing track settlement and significantly reducing noise.

High-speed rail does not use a ballast layer under the tracks, due to its high speed.

The non-ballasted tracks of high-speed rail are not only stable but also enhance passenger safety. Thanks to this design, high temperatures and vibrations from the train running on the tracks are better dispersed, maintaining a consistent distance between the rails and minimizing the risk of accidents. This is particularly important for high-speed trains, where the speeds are significantly greater.

Furthermore, the absence of ballast under the tracks reduces the daily maintenance workload for staff, decreases dust, and enhances the surrounding environment. The gaps between the stones in traditional tracks are often used for rainwater drainage, but with the new technology, rainwater can still be effectively managed without the need for a ballast layer.

The stability of high-speed rail not only ensures safety for passengers but also provides numerous other advantages. Those who have experienced high-speed trains can feel the smooth and comfortable ride. The non-ballasted tracks minimize maintenance workload, allowing staff to focus on ensuring safety and operational efficiency.

The absence of ballast under the tracks also helps reduce the daily maintenance workload for staff.

Without a ballast layer under the tracks, the surroundings of high-speed rail lines also become cleaner and more aesthetically pleasing. This not only improves aesthetics but also minimizes dust pollution, contributing to environmental protection.

The evolution of the railway industry from traditional to modern has brought about significant changes. While the use of ballast in traditional tracks plays a vital role in absorbing vibrations and maintaining safety, modern technology has replaced the ballast layer with more sustainable and efficient materials in high-speed rail systems. These advancements not only enhance speed and operational efficiency but also provide numerous environmental and safety benefits for passengers.