A simple, cost-effective process that produces materials easily applicable in transportation and aerospace.

A team of Chinese scientists has developed a technique that enhances the heat resistance of aluminum alloys, addressing the limitations of this lightweight metal, which is a crucial component in fields such as aerospace and transportation.

Aluminum alloys are known for their low density, exceptional strength, and corrosion resistance. However, their heat resistance has been relatively limited until now. Traditional aluminum alloys typically withstand temperatures of around 350 degrees Celsius. At the threshold of 400 degrees Celsius, the mechanical properties of this material quickly deteriorate, limiting its usability in aerospace designs.

This new aluminum alloy is more than 6 times stronger than traditional aluminum alloys.

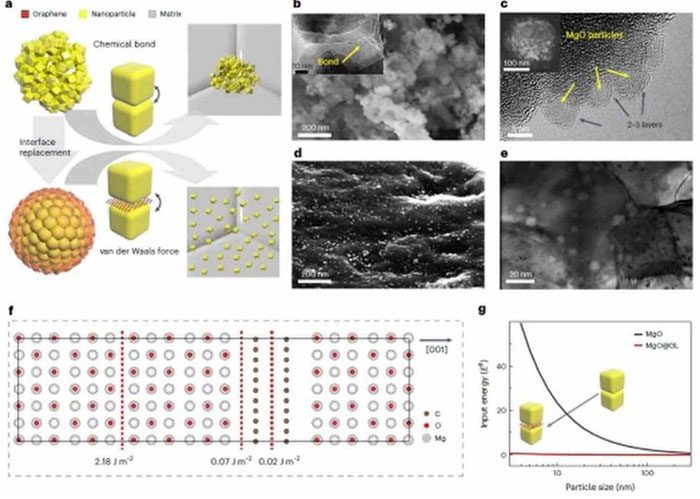

By adding nanoparticles to conventional aluminum alloys, scientists from the Tianjin University (TJU) have created a more durable aluminum alloy that can perform well even at significantly higher temperatures.

In an official statement earlier this month, TJU announced that this new aluminum alloy is more than 6 times stronger than traditional aluminum alloys and surpasses all the best-known aluminum materials worldwide.

Research team leader He Chunnian stated: “This production process is simple, cost-effective, and easily scalable for industrial production, making it highly valuable for industrial applications.”

The research expert further mentioned that the team is collaborating with research organizations and industry leaders to promote the development of heat-resistant aluminum alloys for use in aerospace engines, hoping this material will soon be utilized in the industry.

The study was published on April 26 in the journal Nature Materials.

As mentioned earlier, the heat resistance of aluminum alloys is enhanced by incorporating high-stability oxide nanoparticles. In addition to being cost-effective, these particles, which have melting points above 1,000 degrees Celsius, also exhibit superior strength, thermal conductivity, heat resistance, oxidation resistance, and corrosion resistance.

The process of incorporating nanoparticles into the alloy to create oxide dispersion strengthened (ODS) alloys has shown great promise. In 2022, NASA revealed a similar method for producing the GRX-810 nickel-based alloy, capable of withstanding temperatures up to 1,093 degrees Celsius.

According to NASA’s website, this method has significantly improved the durability of components used in aerospace and space exploration, providing better and longer-lasting performance.