Microsoft and Hewlett Packard Enterprise (HPE) are collaborating with NASA scientists to develop an AI system for inspecting astronauts’ gloves. The harsh environment of space makes equipment failures both common and potentially catastrophic.

Gloves are often prone to wear and tear as they are used for various tasks, including repairing equipment and installing new devices. (Image: Pinterest).

Currently, astronauts send images of their gloves back to Earth for NASA analysts to conduct manual inspections (visual observations through images).

Tom Keane, Vice President of Mission Engineering at Microsoft, stated in a blog post: “This process is completed at the low Earth orbit of the ISS, approximately 250 miles from Earth, but things will be different when NASA sends humans to the Moon or Mars – which is 140 million miles away.”

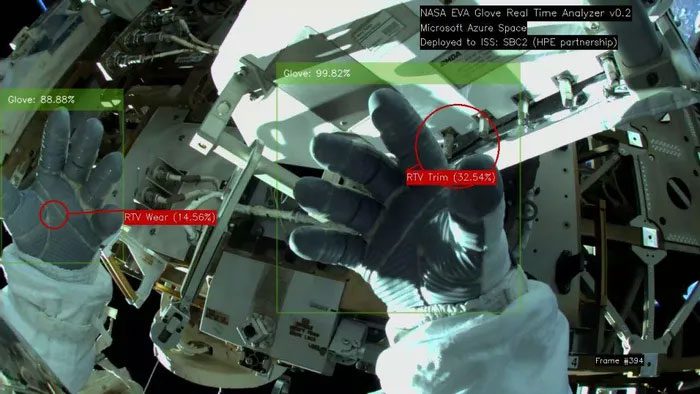

Description of images returned by NASA’s analysis system. (Image: AI News).

Leveraging the power of HPE’s Spaceborne Computer-2, teams from the three companies are developing an AI system capable of quickly detecting even the slightest signs of wear on astronauts’ gloves that could affect their safety.

Astronaut gloves are designed to be durable and consist of five layers. The outer layer has a rubber coating for grip and serves as the first line of defense. Next is a Vectran layer (a cut-resistant material). The last three layers maintain pressure and protect against the extreme temperatures of space.

However, the space environment is too harsh and can compromise these protective layers. Astronaut gloves face many more hazards than what occurs on Earth.

For instance, microscopic materials create sharp edges on handrails and other components. When reaching locations like the Moon and Mars, the lack of natural erosion means that rock particles become more glass-like than simple sand.

Space gloves endure more damaging impacts than those on Earth. (Image: NBC News).

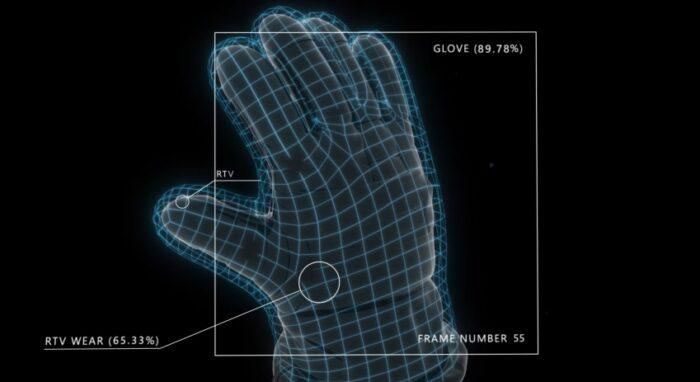

To create the glove analysis tool, the project team began with images of new, undamaged gloves and those showing wear characteristics from spacewalks and terrestrial training. NASA engineers reviewed the images and tagged specific clothing types through Azure Cognitive Services’ Custom Vision.

The cloud-based AI system was trained using data and results that could be compared with NASA’s actual damage reports. The tool generates specific probabilities of damage for areas of each glove.

In space, images of astronauts’ gloves will be captured as they remove their equipment in the spacecraft. These images will then be analyzed locally using HPE’s Spaceborne Computer-2 to identify signs of damage, and if any are found, a notification will be sent to Earth with marked areas for NASA engineers to review further.

How AI scans to analyze astronauts’ gloves. (Image: Root Nation).

Ryan Campbell, a senior software engineer at Microsoft Azure Space, stated: “What we have demonstrated is that we can perform AI processing and edge computing on the ISS and analyze gloves in real-time. Because we can be alongside the astronauts while processing, we can run our tests faster than images can be sent down to Earth.”

The project is an excellent example of the power of AI combined with edge computing in fields with limited connectivity, such as space.

In the future, the project could expand to early detection of damage in other areas, such as hatch installations, before they become serious issues. Microsoft even envisions that a device like HoloLens 2 or a successor device could be used to allow astronauts to visually scan for damage in real-time.

Jennifer Ott, Data and AI Specialist at Microsoft, concluded: “Bringing cloud computing power to the highest levels through projects like this helps us explore and prepare for what we can do next more safely, such as anticipating future human deep-space flights as we begin to push the edge further out.”