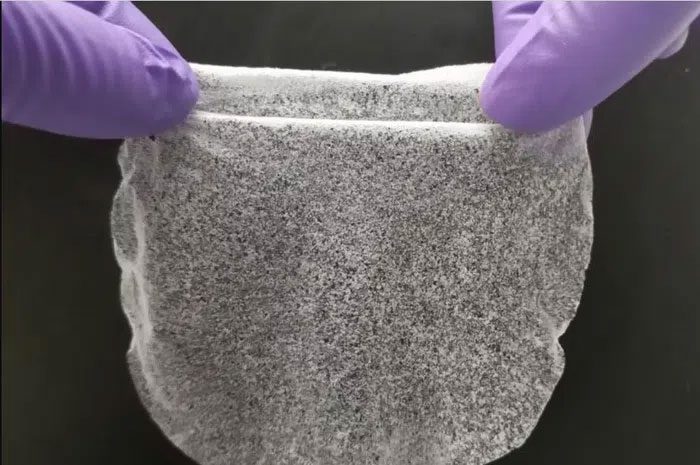

This type of gel is composed of two main, inexpensive, and widely available components: cellulose—derived from plant cell walls—and konjac gum, a commonly used food additive. These two components work together to create a gel membrane that can absorb moisture from the air and then release it on demand without requiring much energy.

Initially, the porous structure of konjac attracts condensed water from the surrounding air. Meanwhile, cellulose is designed to react to slight temperature changes by switching to a hydrophobic mode, releasing the trapped water.

The gel membrane can absorb an incredible amount of water from the air.

The research team stated that creating the gel is quite simple. The basic components are mixed together and then poured into molds, setting for two minutes. After that, it is freeze-dried and removed from the mold. Essentially, it can be formed into any shape necessary and can be easily scaled up at a low cost.

In tests, the gel membrane was able to absorb an astonishing amount of water from the air. At a relative humidity of 30%, it can generate 13 liters (3.4 gallons) of water per day for each kilogram of gel, and even when humidity drops to just 15%—typical of desert air—it can still produce over 6 liters (1.6 gallons) per day for each kilogram.

This represents a significant improvement over other water harvesting devices mentioned in previous years. The previous high was 8.66 liters (2.3 gallons), but that was in much more humid air. Other devices peaked at 5.87 liters (1.55 gallons) at 30% humidity, or as low as 1.3 liters (0.3 gallons).

The effectiveness of the new gel membrane can be further enhanced, the research team noted, by creating thicker membranes, absorbent layers, or other forms of the material. Perhaps most importantly, this material is extremely cheap to produce, costing only about $2 per kilogram. This is another key factor in scaling up the technology and bringing it to remote areas and developing countries where it is needed most.