A research team at SHTP – Labs has developed star-shaped gold nanoparticles (goldstar) that eliminate over 90% of bacteria, which can be applied in health care products.

The product, created by Master Huỳnh Trọng Phát (37 years old, team leader) along with 8 associates at the Research and Development Center, Ho Chi Minh City High-Tech Park (SHTP – Labs), has been in research since 2018 with the goal of creating a new material with high antibacterial properties that is safe for users.

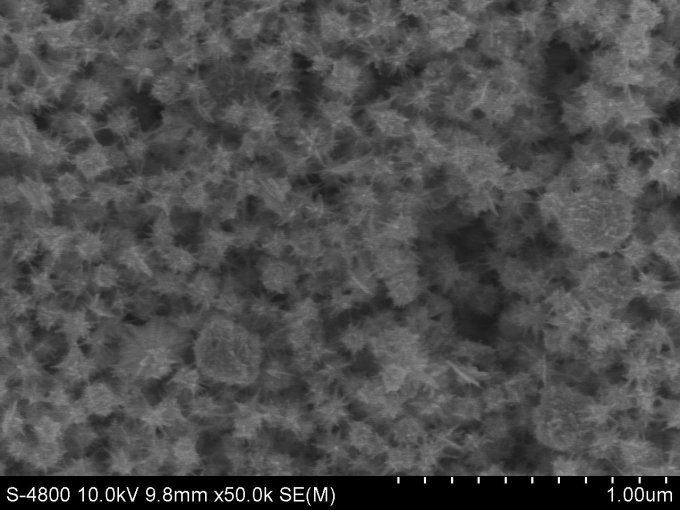

Phát stated that recent studies on gold nanoparticles have primarily focused on spherical forms, aimed at developing anti-aging, antioxidant, and skincare products. However, their antibacterial efficacy has been quite low. In contrast, star-shaped gold nanoparticles demonstrate significantly higher antibacterial effectiveness. This structure is a form of anisotropic nanoparticles that, upon contact with bacteria, can eliminate them through three main mechanisms: disrupting bacterial cell walls, invading bacterial aggregates, and inhibiting bacterial growth, which helps treat various skin conditions such as acne and mild to moderate skin damage.

Scientists at SHTP – Labs researching star-shaped gold nanoparticles. (Photo: Hà An)

To create star-shaped gold nanoparticles, the team utilized biocompatible materials extracted from natural sources, such as chitosan from crab shells and reducing agents like vitamin C. Along with gold salt HAuCl4, biopolymers, and vitamin C, the researchers employed chemical reactions to synthesize the star-shaped gold nanoparticles.

According to the research team, the main difference between creating spherical gold nanoparticles and star-shaped ones lies in the temperature used during the reaction process. The team conducted experiments to determine the optimal temperature.

Using natural substances ensures safety for users; however, the team assessed that the yield was not particularly high. “This is considered a limitation of this method. To partially overcome this, we employed ultrasonic waves to provide energy, increasing the yield of goldstar nanoparticles, which are several tens of nanometers in size, suspended in water.”

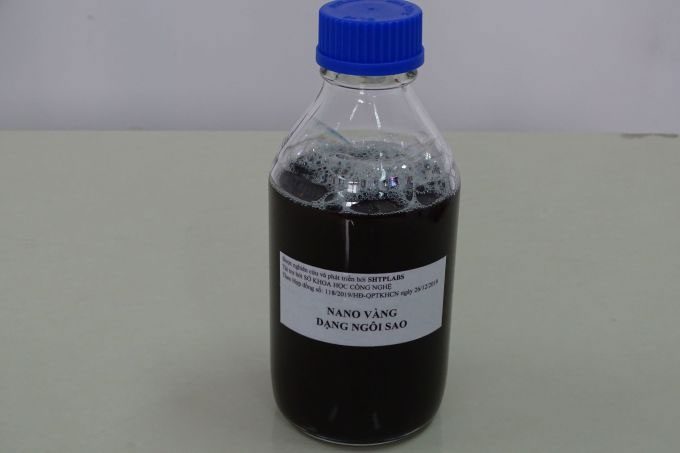

The final product of gold nanoparticles in water. (Photo: Hà An).

According to Phát, the most challenging step in creating goldstar nanoparticles is controlling the desired shape regarding size and material length in the star structure to achieve the highest efficiency. The amount of gold used to create the nanoparticles is very small, only a few tens of micrograms per milliliter of solvent. This keeps the commercialization costs relatively low. “Gold is inherently human-friendly, with high biocompatibility. Our research method follows green principles, making it feasible for commercialization.” Goldstar nanoparticles can be attached to other material surfaces, such as fabrics for bandages, aiding in faster wound healing or serving as a primary ingredient in acne treatment gels.

The goldstar nanoparticles product is being tested in collaboration with Mediworld and other units, undergoing cell-level, animal, and human trials according to the A-class medical equipment standards (low-risk level) set by the Ministry of Health. Test results indicate that the acne treatment gel is effective after 1 to 6 months of use, depending on the severity of the condition.

Star-shaped nanoparticles under an electron microscope. (Photo: NVCC).

According to Dr. Ngô Võ Kế Thành, Director of SHTP – Labs, goldstar nanoparticles represent a research direction that has garnered international scientific interest in recent years, with numerous scientific publications. Currently, there are not many research teams in the country pursuing this direction.

He noted that this technology could be developed into various products in the biomedical field, aiding in cancer treatment, and creating biosensors for disease detection. “Currently, the product is being commercialized in collaboration with businesses, with initial revenues reaching hundreds of millions of VND from the acne treatment gel. We will continue to work with the team to seek licensed bandage manufacturers to apply this in developing disinfectant products for patients,” Dr. Thành stated.