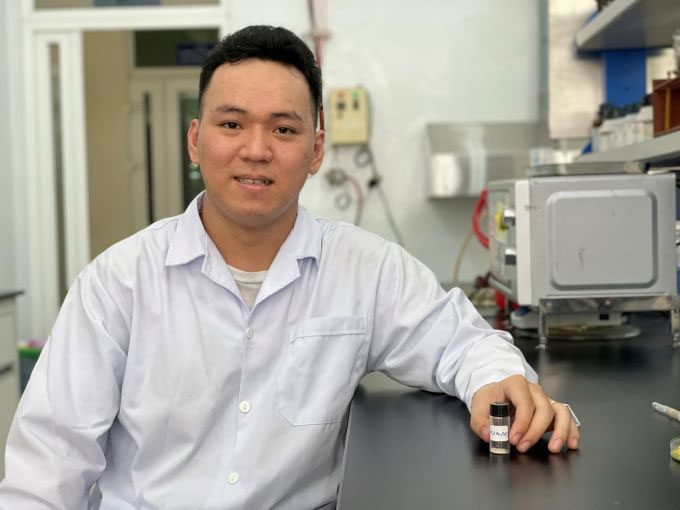

Master Ho Gia Thien Thanh, 26 years old, is researching gold nano catalysts to reduce the toxicity of p-nitrophenol found in wastewater into a non-toxic form, with applications in the pharmaceutical industry.

Thanh currently works at the Department of Process Equipment and Catalysis, Institute of Chemical Technology, Vietnam Academy of Science and Technology. Since late 2022, Thanh has been researching and proposing a process for the synthesis of gold nano catalysts using an environmentally friendly method called ceria nanorods to reduce p-nitrophenol (PNP) in wastewater. PNP is an organic compound that poses toxicity risks and is commonly found in wastewater from dyeing, pharmaceuticals, and food processing industries. The U.S. Environmental Protection Agency has classified it as one of the 114 most dangerous organic pollutants and a potential carcinogen.

Master Ho Gia Thien Thanh in the laboratory at the Institute of Chemical Technology, Vietnam Academy of Science and Technology (District 12, Ho Chi Minh City). (Photo: Ha An)

The author noted that traditional methods for synthesizing gold nanoparticles often use chemical reducing agents like Sodium Borohydride (NB), which are toxic and expensive. To replace this reducing agent, Thanh used grapefruit peel extracts, rich in polyphenol compounds capable of reducing gold ions into gold nanoparticles.

Additionally, to enhance the efficiency of converting PNP to PAP, the author utilized ceria nanorods as a carrier to help disperse the gold nanoparticles, thereby reducing the processing time from one hour to 30 minutes. “This method makes the PNP reduction process greener, cost-effective, and utilizes natural by-product sources,” Thanh stated.

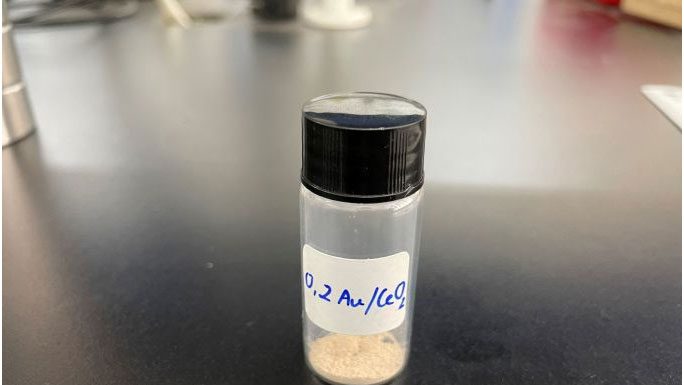

With a gold nanoparticle content ranging from 0.1 to 0.2% on the ceria carrier, the gold nano catalyst operates effectively, achieving over 99% reduction efficiency for PNP in laboratory-scale trials.

After five test batches, the catalyst maintained its activity and efficiency, significantly lowering costs. After each treatment batch, the catalyst can be separated by centrifugation and reused for the next batch.

The author mentioned that the recovery efficiency of PAP, a useful precursor in the pharmaceutical industry, has not yet been calculated as they are still in the early stages of optimizing the synthesis process and its components.

Product used to reduce PNP in wastewater, researched by Thanh. (Photo: Ha An).

According to Dr. Nguyen Tri from the Institute of Chemical Technology, Vietnam Academy of Science and Technology, using catalysts to convert PNP into PAP is not a new research direction in the country. However, the novelty of this research lies in applying green methods that utilize plant extracts, specifically grapefruit peel, a common by-product for synthesizing gold nanoparticles attached to ceria carriers. This approach uses low gold content, yet achieves high efficiency and stable catalyst durability.

For higher applicability, Dr. Tri suggested that the author should develop catalysts in pellet form or affixed to a substrate for easier recovery. This research also needs to be tested on a larger scale with wastewater to evaluate the impact of other substances present in the water affecting PNP reduction efficiency.

This research is part of the Young Creative Startup Incubator Program of Ho Chi Minh City Youth Union, which has recently received excellent appraisal. Assoc. Prof. Dr. Nguyen Thi Phuong Phong, Chair of the Expert Council, praised the author’s use of grapefruit peel extract to reduce gold salts to gold nanoparticles, converting toxic substances into non-toxic forms for pharmaceutical applications.

Current methods for treating PNP mainly use adsorption technology, but these require a subsequent step to process the adsorbent. Other traditional methods involve various chemicals that are costly and environmentally damaging.