The bionic leg developed by Dr. Tran Minh (28 years old) weighs only 3 kg, allowing patients with limb loss to walk comfortably like normal.

Utah Bionic Leg was created by Dr. Minh and his colleagues at HGN Lab, University of Utah (USA) starting in 2017. The leg is designed to weigh 3 kg, which is half the weight of other prosthetic legs on the market. The length of the leg can be adjusted according to the user’s height and the length of the amputated limb. The device is designed to effectively support movement for users weighing under 125 kg.

Dr. Lukas Grabert, a member of HGN Lab, stated that the team researched the mechanics of human legs and discovered that agile and effective movement is due to passive dynamics. This means that when inertia and gravity interact with limbs during movement. Based on this mechanism, the team designed the drive system in the bionic leg, which helps adjust the leg’s configuration passively while in motion.

(Video: YouTube channel of the John and Marcia Price College of Engineering, University of Utah).

The product consists of two main parts: the knee joint and the ankle joint, the foot. Each joint is equipped with an electric motor, sensors, a microprocessor, a battery system, an electrical circuit, and artificial intelligence (AI). These components work in sync to perform all the primary movement functions of the leg such as walking, standing up, sitting down, and moving on slopes and stairs.

The leg is designed with a specialized smart drive system in three components. The knee joint optimizes operational power and saves battery. The ankle/foot drive system is developed based on the tendon system in human feet. Finally, the ankle/foot is connected to the toe joint by a spring system that helps support patients in natural movement and balance on various surfaces and weather conditions.

When users move, the sensors and systems equipped in the bionic leg transmit information to the AI microprocessor about the activity status and movement level. The system determines the user’s intent to provide appropriate support. The product also features a low-energy mode for extended periods, allowing users to maintain movement without losing strength.

Dr. Tran Minh assembling the bionic leg in the lab. (Photo: NVCC).

Dr. Minh noted that prosthetic products require installation at hospitals for doctors and specialists to adjust according to the patient’s height and weight and to guide safe movement.

According to the research team, existing prosthetics on the market are designed as shock-absorbing components and are mechanically passive. This means they lack motors and the flexibility of natural limbs. These products require patients to be in good physical condition and take a long time to adapt.

The Utah bionic leg overcomes the limitations of traditional prosthetics. The engineers at HGN Lab designed mechanical details and electrical circuits, which were then manufactured according to specifications. These parts are sent to the lab for assembly, software installation, and fine-tuning to optimize functionality. “With the Utah bionic leg, the adjustment process for users will be quicker because of the assistive system,” Dr. Minh said.

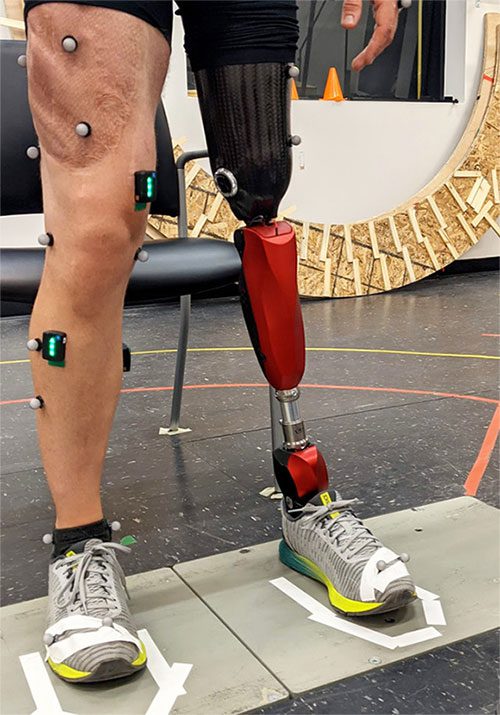

The device being tested with a leg amputee. (Photo: Research Team).

After testing the device on more than 20 patients since 2020, the research team reported positive feedback from users. Many patients can perform essential movements that they could not do with conventional prosthetics, such as going up and down stairs or sitting up independently without assistance.

“Our product is the first bionic leg in the world that allows a person with bilateral amputations to walk comfortably,” Dr. Minh stated. The results of the research have been published in prestigious scientific journals such as Science, Scientific Reports, and IEEE Transactions.

Professor Tommaso Lenzi from the University of Utah, a supervising instructor, noted that the scientific community has been researching prosthetic technology since the 1970s but has not achieved its goals. Currently, mechatronic technology has advanced, as microprocessor batteries for electric motors are becoming faster, smaller, and lighter. Utilizing technological advancements and discoveries about passive dynamics, the Utah bionic leg from the team “with its compact size, will help leg amputees move independently and freely pursue their life goals,” Professor Tommaso Lenzi evaluated.

Dr. Minh mentioned that the team continues to test the feasibility of the Utah prosthetic leg when users utilize it at home for extended periods. Currently, HGN Lab is collaborating with Otto Bock, the world’s largest prosthetic manufacturer based in Germany, to mass-produce the Utah bionic leg as a medical product for users in the shortest time possible, at a price comparable to traditional prosthetic models.

| Dr. Tran Minh was born and raised in Hanoi. Minh completed his high school program at Hanoi-Amsterdam High School in 2013. He went to the USA to study for a bachelor’s degree in mechanical engineering at the University of Utah and earned his PhD in May 2023. In 2015, Dr. Minh began designing robots with a primary research focus on flexible and high-functioning limb joints. He currently works as a design engineer for Agility Robotics, a robotics company in the USA. |