Master Tran Le Trung Chanh from the University of Can Tho’s Faculty of Engineering has successfully developed an automatic lemon peeling machine, achieving an initial model that can process 240 lemons per hour.

In 2016, Master Chanh and a working group from the University of Can Tho researched the application needs and technology innovations in Hau Giang. He observed that several households were manually peeling lemons or using semi-automatic machines with low efficiency.

At that time, there were many automatic lemon peeling machines available on the market, but most required users to sequentially place each lemon into the peeling or raw material area, resulting in wasted effort and time for workers, with low automation. From this reality, Master Chanh set the goal to create a fully automatic lemon peeling machine. The operator only needs to load multiple lemons into the feeding area once, after which the system automatically locates each lemon and delivers it to the peeling knife.

Testing the operation of the automatic lemon peeling machine. (Video: NVCC).

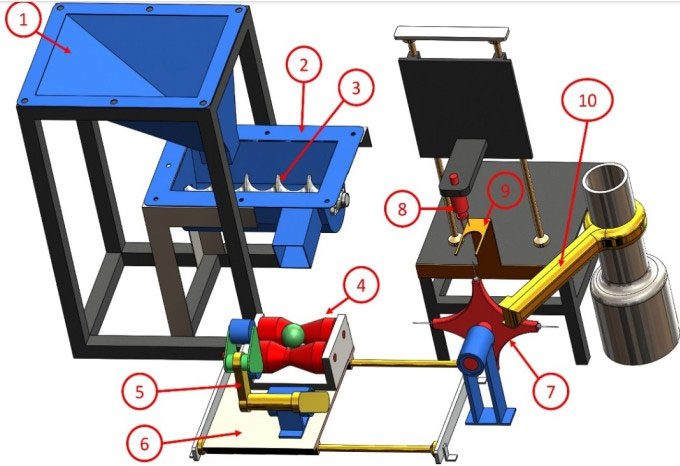

After more than a year of research, the author successfully constructed the automatic lemon peeling machine, which consists of five main components: the raw feeding section, orientation, pin, rotation, and peeling knife. When the machine is activated, the lemon is fed into the material compartment and falls into a funnel with a helical screw conveyor. Each lemon is then moved to the position of the centrifugal roller mechanism for orientation. The pin head then holds and rotates the lemon 90 degrees to an upright position. At this point, the opposing pin head descends to hold the other end of the lemon while it rotates. The peeling knife then approaches the rotating lemon to perform the peeling operation in an upward arc until the entire surface of the lemon is peeled. After completion, the rotating pins stop, and the peeling knife halts, concluding the peeling process and repeating the cycle with the next lemon.

Test results showed that the machine achieved an average peeling efficiency of 85% of the lemon’s surface, with a productivity rate of 240 lemons per hour, equivalent to 24 kg of peel. According to Master Chanh, the cleanliness of the peel depends on the depth of the peeling and the cut thickness (the width of the peel after cutting) from the fruit. The author assessed that an average peeling depth of 1.86 mm and an average cut thickness of 3.1 mm are optimal.

The product he developed is currently in its first version, so the productivity is still low, and the cleanliness of the peel has not yet reached perfection. Currently, the machine can peel medium-sized lemons and larger.

The author indicated that future improvements will focus on adapting the mechanisms to accommodate all sizes of lemons, maximizing the peeling capacity for the various types of lemons available. The machine will also be designed to include compartments for the peels and the fruit after peeling. He also plans to develop a pineapple peeling machine based on the lemon peeling machine’s mechanism.

Design diagram of the author’s lemon peeling machine. (Photo: NVCC).

Mr. Hung Tran, a machine design and fabrication expert, evaluated the product as not being new, but it has practical applications for mechanization in the processing of agricultural products, thereby liberating labor. However, he stated that the machine is still in the model stage with low productivity. Additionally, the positioning mechanisms for the fruit and the fixed pin head are prone to high error rates. He believes that the fixed pin head for the lemon must be robust to prevent any impact on the peeling process due to high-speed rotation, ensuring the fruit does not fly out. “The author needs to optimize the machine’s mechanical processing by designing components that are sturdy, durable, and operate precisely. This will allow the machine to work continuously without errors, achieving high cleanliness of the peel,” he remarked.